- Joined

- Nov 22, 2010

- Messages

- 371

i stopped by a local used shop equiptment shop today to get a fly cutter and casually asked if any small lathes had come in......

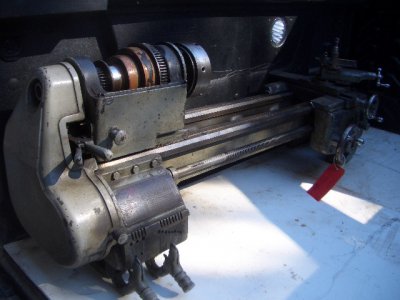

he said there was a 10" logan that came in last thursday. it is on the origional legs with stock chip pan and has 2 complete sets of 3C collets and two draw bars ( he is keeping on set) it has 2 ..3jaw chucks one 4 jaw chuck a steady rest and a pile of bits and pieces.

The post that suports the belt drive is in place all the covers are unbent and in good shape. the ways ar about perfect . the origional forward /reverse switch has been replaced with a newer square D controler an looks quite new but the paint is origional and in obviously has some years of wear but it is clean... the Bull gear is missing teeth in two places and all the other gears are fine. it came from a factory that made paper bags and this lathe was used fo make needed parts to keepthe bags going so it was more or lesss atool room usage machine, not production.

i see abull gear advertised for a monkey ward Power-craft 10" lathe will that fit this model 820 logan 10 inch ???

I have seen bull gears that were filled with brazing and the missing teeth recut ??? Is this an acceptable repair or is it a wast of time and money

anybody know of another Bull gear available?

joe

he said there was a 10" logan that came in last thursday. it is on the origional legs with stock chip pan and has 2 complete sets of 3C collets and two draw bars ( he is keeping on set) it has 2 ..3jaw chucks one 4 jaw chuck a steady rest and a pile of bits and pieces.

The post that suports the belt drive is in place all the covers are unbent and in good shape. the ways ar about perfect . the origional forward /reverse switch has been replaced with a newer square D controler an looks quite new but the paint is origional and in obviously has some years of wear but it is clean... the Bull gear is missing teeth in two places and all the other gears are fine. it came from a factory that made paper bags and this lathe was used fo make needed parts to keepthe bags going so it was more or lesss atool room usage machine, not production.

i see abull gear advertised for a monkey ward Power-craft 10" lathe will that fit this model 820 logan 10 inch ???

I have seen bull gears that were filled with brazing and the missing teeth recut ??? Is this an acceptable repair or is it a wast of time and money

anybody know of another Bull gear available?

joe