-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

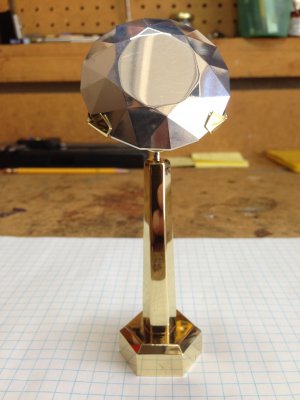

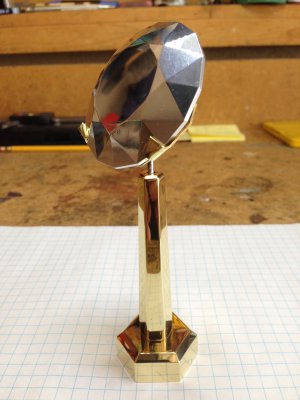

A Diamond Is Forever

- Thread starter Fabrickator

- Start date

- Joined

- Jan 22, 2014

- Messages

- 578

Sorry, but I'm not sure what you're talking about. If you mean how I cut the 73 facets I just set the appropriate angle(s), figured out the index (8's and 16's) and used the spec/guide sheet to guide my depths, widths and general % measurements for each area called out in the guide. Most of all, I wanted it to be flawless and accurate, like a real stone, so I took my time (about 24 hrs. over 2 weeks/not including polish time).

I cut all of it with one 1/2" 2-flute TIN coated end mill and got a pretty acceptable finish using my power feed on slow feed speeds. Instead of using my 8" cotton buffing wheel and chance losing the edges, I bought a vibration tumbler with corn cob media and it worked great for a "set-it and forget it" polish (about 12 hrs.) and I finished with a quick hand job of Mother's. I'm working on a small brass stand for it now so I can spin it around for a 360* view.

I got a similar 2" round bar of stainless, so I may try it again.

LMS High Torque Mini Mill

LMS Rotary Table & Power Feed

Grizzly G0602

Rick

I cut all of it with one 1/2" 2-flute TIN coated end mill and got a pretty acceptable finish using my power feed on slow feed speeds. Instead of using my 8" cotton buffing wheel and chance losing the edges, I bought a vibration tumbler with corn cob media and it worked great for a "set-it and forget it" polish (about 12 hrs.) and I finished with a quick hand job of Mother's. I'm working on a small brass stand for it now so I can spin it around for a 360* view.

I got a similar 2" round bar of stainless, so I may try it again.

LMS High Torque Mini Mill

LMS Rotary Table & Power Feed

Grizzly G0602

Rick

- Joined

- Jan 22, 2014

- Messages

- 578

- Joined

- Dec 31, 2010

- Messages

- 937

Facinating work. very pretty.

Ray

Ray

- Joined

- May 16, 2016

- Messages

- 1,693

Looks great. You could try it again with clear polycarbonate and see how it looks