-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

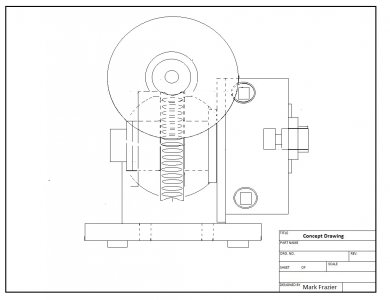

A Dividing Head Anyone Can Build

- Thread starter Mark_f

- Start date

I was scratching my head about that vertical position on the first one.

The worm was going to hit on the first one.

I got started on the dividing head. I roughed out the body and cut the slot for the gear.

I turned a piece of 3 inch diameter stock to true it up and clean it up, cut a step on one end and cut the slot for the gear to set in. The slot was cut by drilling through a 3/4" hole at the bottom of the slot and cutting the sides down to the hole and removing most of the material.

I turned a piece of 3 inch diameter stock to true it up and clean it up, cut a step on one end and cut the slot for the gear to set in. The slot was cut by drilling through a 3/4" hole at the bottom of the slot and cutting the sides down to the hole and removing most of the material.

The picec was setup like in this photo to trimm up the sides and bottom of the slot with a 1 inch end mill.

The picec was setup like in this photo to trimm up the sides and bottom of the slot with a 1 inch end mill.

The gear fits the slot good. The next step will be to bore the hole for the spindle. This will be done on my lathe with the milling table installed.

The gear fits the slot good. The next step will be to bore the hole for the spindle. This will be done on my lathe with the milling table installed.

These two photos are the piece set up on the lathe for boring the spindle hole. I will start this tomorrow.

These two photos are the piece set up on the lathe for boring the spindle hole. I will start this tomorrow.

I am not sure this design will even work, but think enough of it to give it a try. This is my attempt to make a head I can use horizontally and vertically. If it doesn't work out, I will start over and just go with a horizontal head.

I turned a piece of 3 inch diameter stock to true it up and clean it up, cut a step on one end and cut the slot for the gear to set in. The slot was cut by drilling through a 3/4" hole at the bottom of the slot and cutting the sides down to the hole and removing most of the material.

I turned a piece of 3 inch diameter stock to true it up and clean it up, cut a step on one end and cut the slot for the gear to set in. The slot was cut by drilling through a 3/4" hole at the bottom of the slot and cutting the sides down to the hole and removing most of the material. The picec was setup like in this photo to trimm up the sides and bottom of the slot with a 1 inch end mill.

The picec was setup like in this photo to trimm up the sides and bottom of the slot with a 1 inch end mill. The gear fits the slot good. The next step will be to bore the hole for the spindle. This will be done on my lathe with the milling table installed.

The gear fits the slot good. The next step will be to bore the hole for the spindle. This will be done on my lathe with the milling table installed.

These two photos are the piece set up on the lathe for boring the spindle hole. I will start this tomorrow.

These two photos are the piece set up on the lathe for boring the spindle hole. I will start this tomorrow.I am not sure this design will even work, but think enough of it to give it a try. This is my attempt to make a head I can use horizontally and vertically. If it doesn't work out, I will start over and just go with a horizontal head.

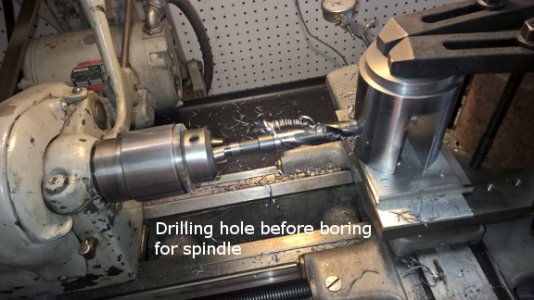

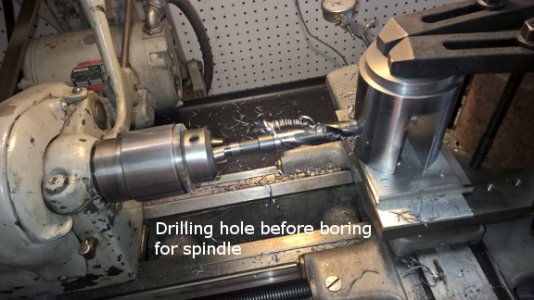

OK.... Since I had the body set up to bore , I got started this morning. I started by drilling a 3/4" hole through the body.

drilling the starter hole here.

drilling the starter hole here.

Put my boring head conversion (that I invented) on my 4 jaw chuck to bore the spindle holes.

Put my boring head conversion (that I invented) on my 4 jaw chuck to bore the spindle holes.

Boring the holes. I first bored to .875" which will be the size of the rear shaft. Then bored the front hole to 1.624 which is .001" smaller than the size of the bronze bearing that holds the 1.250 spindle. The front is larger and has the bronze bearing to support the 4 ' chuck.

Boring the holes. I first bored to .875" which will be the size of the rear shaft. Then bored the front hole to 1.624 which is .001" smaller than the size of the bronze bearing that holds the 1.250 spindle. The front is larger and has the bronze bearing to support the 4 ' chuck.

The hole came out perfect. The bearing went in with a few light taps with a mallet.

The hole came out perfect. The bearing went in with a few light taps with a mallet.

The bearing extends .020" into the slot for the worm wheel to ride against.

The bearing extends .020" into the slot for the worm wheel to ride against.

Next , the shaft has been rough turned. I left .020" on all the surfaces. I will let it cool and finish it to size and polish it in the morning.

Next , the shaft has been rough turned. I left .020" on all the surfaces. I will let it cool and finish it to size and polish it in the morning.

I sure hope this idea works as I now have a lot of work in it . It will be wider than I wanted but that is unavoidable due to the diameter of the gear, but I think it will be fine

. It will be wider than I wanted but that is unavoidable due to the diameter of the gear, but I think it will be fine  , we shall see.

, we shall see.

drilling the starter hole here.

drilling the starter hole here. Put my boring head conversion (that I invented) on my 4 jaw chuck to bore the spindle holes.

Put my boring head conversion (that I invented) on my 4 jaw chuck to bore the spindle holes. Boring the holes. I first bored to .875" which will be the size of the rear shaft. Then bored the front hole to 1.624 which is .001" smaller than the size of the bronze bearing that holds the 1.250 spindle. The front is larger and has the bronze bearing to support the 4 ' chuck.

Boring the holes. I first bored to .875" which will be the size of the rear shaft. Then bored the front hole to 1.624 which is .001" smaller than the size of the bronze bearing that holds the 1.250 spindle. The front is larger and has the bronze bearing to support the 4 ' chuck. The hole came out perfect. The bearing went in with a few light taps with a mallet.

The hole came out perfect. The bearing went in with a few light taps with a mallet. The bearing extends .020" into the slot for the worm wheel to ride against.

The bearing extends .020" into the slot for the worm wheel to ride against. Next , the shaft has been rough turned. I left .020" on all the surfaces. I will let it cool and finish it to size and polish it in the morning.

Next , the shaft has been rough turned. I left .020" on all the surfaces. I will let it cool and finish it to size and polish it in the morning.I sure hope this idea works as I now have a lot of work in it

, we shall see.

, we shall see.

Last edited by a moderator:

Looks like an excellent project(!) - I am hoping to do something similar (or the same) in the near future. As comparative newcomer I need to work on some simpler projects before tackling the Dividing Head. Non the less, I look forward to watching your project develop and learning from what you do and how you do it.

Many thanks, Arthur

Many thanks, Arthur

Looks like an excellent project(!) - I am hoping to do something similar (or the same) in the near future. As comparative newcomer I need to work on some simpler projects before tackling the Dividing Head. Non the less, I look forward to watching your project develop and learning from what you do and how you do it.

Many thanks, Arthur

This dividing head is really pretty simple. My intention is to make it as easy as possible for anyone to be able to do and a dividing head is something most of us want and can use.