-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

A Dividing Head Anyone Can Build

- Thread starter Mark_f

- Start date

- Joined

- Sep 5, 2014

- Messages

- 4

What a project and the word "nicely done" can't even describe it. Bravo.

Wondering.... I've got an older Ellis divider and it's without its handle. I've looked far and wide for plans for a replacement indexing pin handle that I could copy. Yours fit the bill. By chance do you have the drawings you made for yours available? It would be much appreciated to complete my build.

Again great work.

Best.

Wiredodger60

Wondering.... I've got an older Ellis divider and it's without its handle. I've looked far and wide for plans for a replacement indexing pin handle that I could copy. Yours fit the bill. By chance do you have the drawings you made for yours available? It would be much appreciated to complete my build.

Again great work.

Best.

Wiredodger60

What a project and the word "nicely done" can't even describe it. Bravo.

Wondering.... I've got an older Ellis divider and it's without its handle. I've looked far and wide for plans for a replacement indexing pin handle that I could copy. Yours fit the bill. By chance do you have the drawings you made for yours available? It would be much appreciated to complete my build.

Again great work.

Best.

Wiredodger60

Actually there are no drawings for the dividing head. I built it on the fly by the seat of my pants, so to speak. How ever, I can make you a rough drawing of how I made the handle. I made three handles before I got one I liked. I will try to make you a drawing later today.

- Joined

- Jul 16, 2013

- Messages

- 43

I did not spend the time to read trough all the posts but if this was said before , sorry. Deansphotographica - Link below has a super step by step on building a simple dividing head in fact this is on which I based my idea when I build mine and well worth a look over - the man is , imo , a legend when you see what he has accomplished with such a small kit!

The Link to his page:

http://www.deansphotographica.com/machining/projects/divider/dividinghead.html

Best regards

Paul

The Link to his page:

http://www.deansphotographica.com/machining/projects/divider/dividinghead.html

Best regards

Paul

What a project and the word "nicely done" can't even describe it. Bravo.

Wondering.... I've got an older Ellis divider and it's without its handle. I've looked far and wide for plans for a replacement indexing pin handle that I could copy. Yours fit the bill. By chance do you have the drawings you made for yours available? It would be much appreciated to complete my build.

Again great work.

Best.

Wiredodger60

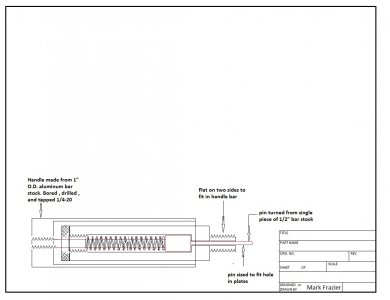

I found a drawing of the handle and plunger assembly. It has no dimensions but you will have to make it to fit your dividing head anyway. I hope this helps you. Any questions just ask me and I will try to help.

- Joined

- Mar 31, 2016

- Messages

- 106

That was a cracking project and a cracking job. Well done.

Wayne

Wayne

- Joined

- May 4, 2015

- Messages

- 3,583

As my tool and die shop teacher would say, well done A+ keep up the good work. Then he would say now what's your next project? Nice job turned out really nice.

- Joined

- Oct 14, 2015

- Messages

- 128

Mark this project is awesome. Just amazing great work.

- Joined

- Aug 3, 2016

- Messages

- 25

I really like your set up to put divisions and stamps, do you have a walk through on those? I thought the first time I saw your divisions, (the ones that are on both sides of the dividing head itself) that they had to be a sticker. The way you held your stamps in place is amazing as well. The project itself as a whole is very well done, I will make this someday and appreciate the time you put into the guide. My very own teacher said it would be worthless to make my own. However the division markings are something that caught my eye because of how professional it makes the total appearance. Great work Mark.

Zach

Zach

And the winner is ..... BLACK WRINKLE FINISH. I painted the first part today and chose the black wrinkle finish because it looks expensive and is durable.

I spent a lot of time figuring out the worm setup to get everything I wanted. This photo is the complete worm assembly. I had to make the eccentric and the hub to hold the index plates in two pieces and lock-tite them together . I cut the flats on the end of the shaft to hold the index handle and made a pretty brass hand wheel to hold the index handle on. I wanted it easy to remove to change plates. I also threaded the shaft and put a lock nut to hold the worm on.

View attachment 103308

View attachment 103309 This is the assembly of what is done so far. The worm mounting plate is painted and mounted. I should not have to disassemble it from the body anymore. There is a set screw in the back side to lock it to the body. It is also a kind of press fit on, so it will not move. it rotates with the body to go to the vertical position. You can also see the fancy brass hand wheel to hold the index handle on. There is a set screw assembly made up of a brass plug and two lock set screws in the front of the plate in the photo. This brass plug provides a little tension on the worm eccentric so it doesn't flop back and forth. It requires a light push to rotate the worm to engage or disengage and it will stay in position until it can be locked. The little 3/16" diameter brass lever sticking up is to engage or disengage the worm by rotating eccentric using this lever. I ordered a nice red knob for it from McMaster Carr. The gears turn very smoothly with almost no detectable back lash ( which is adjustable by the eccentric to be as loose or tight as I want.

View attachment 103316 This is a rear view. The "T" handle is the lock to secure the worm eccentric in position. You can see the trunnion sticking through the plate .150". Originally there was not going to be an outboard trunnion and I still believe it is sturdy enough without it, but I am putting one on. It will be a lighter weight assembly made from 1/4" steel plate. By having it , there will be the little extra support and make things that much sturdier and prevent vibration of the body hanging out there.

View attachment 103317 This plate is the outboard trunnion support. It is 1/4" steel plate. due to the close area of the worm mounting, the trunnion ring is not as heavy as the main support on the other end. You can see a narrowed section for 90 degrees that had to be relieved to allow the rotation to the vertical position. This assembly is heavier than it looks. When the ring is captured between the body and end plate, there is a total thickness of 1/2" of steel clamped up. It will provide more than adequate support on this end.

View attachment 103318 Here the trunnion is mounted. I still have to put the 3/8"-16 bolts in that clamp everything together. There will also be a heavy duty bracket to connect the second trunnion plate to the main base. I still have to drill and tap three 10-24 holes in the plate hub to mount the index plates. This will be done when the plates are made and all drilled at the same time.

In answer to the question asked about a cover for the worm gear to keep swarf out. YES, there will be a cover over the gear. I just haven't designed it yet and it will be one of the last details done. There will be a direct index plate behind the chuck with 24 and 36 holes in it and also marked in degrees. There will be a spring loaded pin to engage this plate when it is in use. I left that flat on the front side of the worm plate to fasten the spindle lock to. Yes, I will need a spindle lock . I also need to make a center and drive dog for working between centers. I have the material for it on hand.

I have tried to put everything in this project that the big honking 200 pound heads have. :

1.) a thirty to one gear ratio which will cover all divisions up to 50 and many others above using a minimum number of holes circles.

2.) 1 1/2"-8 threaded spindle that also accepts 3C collets and utilizes all my lathe chucks and face plates, giving me maximum versatility.

3.) the ability to rotate 90 degrees to the vertical position as well as the horizontal position.

4.) an easy to use eccentric to disengage the worm and allow simple indexing using a plate and spring loaded pin.

5.) A spindle lock to lock the spindle in position.

6.) easy to remove index handle ( no tools needed) and sector arms which will make plate changes simple.

7.) The unit is relatively small but heavy duty and fits nicely on the smaller mills such as the Burke. One person can carry it!

Have I forgotten anything?

Can you go into more detail on the two pieces you put together with locktite? I'm having trouble visualizing this.