When I put the base on my surface plate and ran the clock over it there was only about 0.05mm deviation but I didn't

like all the ridges the cutter had made my biggest cutter is 12mm and the head of the mill is probably not trammed

perfectly, so I decided to scrape the bottom, not bothered about the top it will be painted. I have a surface plate, I found it in a field about

5 years ago it was in a bad state badly pitted and covered with rust, I sanded it down with a belt sander and used it for center punching.

A month ago I managed to borrow a granite surface plate from a friend who uses it for marking out pieces for his model airplanes. You can see it

in one of the previous pic. He's took it back yesterday. Boo!

I decided as my first ever scraping job I was going to scrape my plate flat, I t took 3 weeks every night, no proper scraper and no engineers blue,

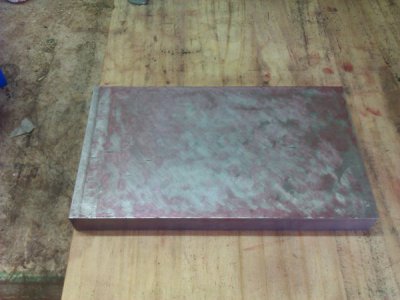

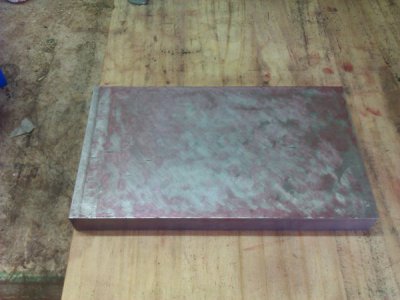

I used tungsten carbide paint scraper and some red paint from a toy shop, but it is flat, nearly! So I scraped the base and from the pic you can see

it is nearly there I will do a bit more tomorrow. I don't like all that striping so I am going to do what Mark did and fly cut the rest, I will make one

tomorrow.