- Joined

- Dec 19, 2018

- Messages

- 128

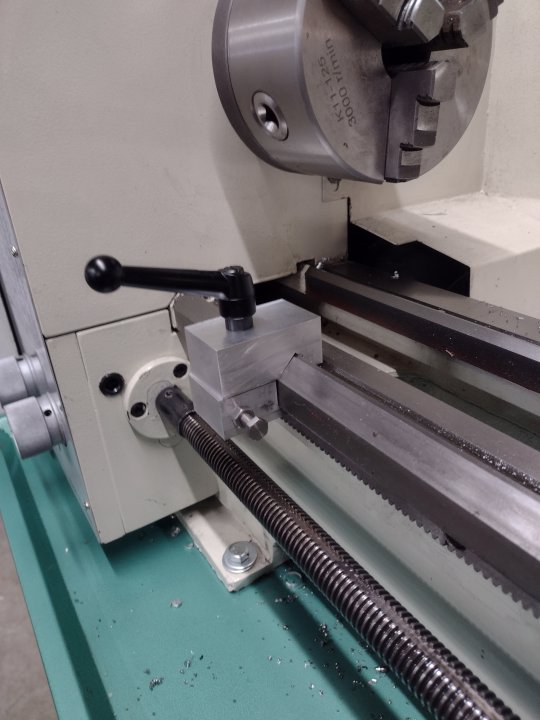

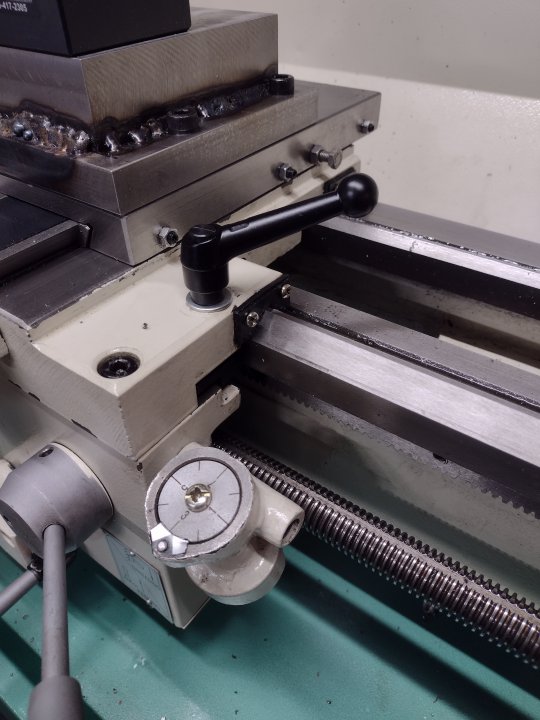

Now that I finished my riser block for my Bostar QCTP I spent some time getting my primary tools centerline adjusted. I also did a few must have mods. I fabbed a carriage stop and I modified the carriage clamp to accept a adjustable clamp lever. I LOVE the versatile MSC adjustable clamp levers !

It's the little upgrades that make your life so much easier and quicker ! The biggest PIA with the carriage clamp was I had to modify the 5/16-18 threads to accept the lathe clamp's M6x1 threads. Drilling out and re-tapping the lower carriage clamp to 5/16-18 was not an option. For the first time I single point threaded M6x1 manually spinning running the chuck . The threads came out perfect but that's a TON of labor. I need to learn how to tap metrics with power feeding.

It's the little upgrades that make your life so much easier and quicker ! The biggest PIA with the carriage clamp was I had to modify the 5/16-18 threads to accept the lathe clamp's M6x1 threads. Drilling out and re-tapping the lower carriage clamp to 5/16-18 was not an option. For the first time I single point threaded M6x1 manually spinning running the chuck . The threads came out perfect but that's a TON of labor. I need to learn how to tap metrics with power feeding.