- Joined

- Jun 12, 2018

- Messages

- 712

My Grizzly G8688 Mini Metal Lathe 7 x 12-Inch just came in this afternoon and I have a few questions

-This is my first ever using a lathe. When I turn the chuck, it seems like it's a tad harder and "rough." I don't know if this is normal or not.

-I bought the 3/8" carbide insert cutters. Which one is which? Which one is for turning, facing, etc.. I know the "E" one is for V grooving.

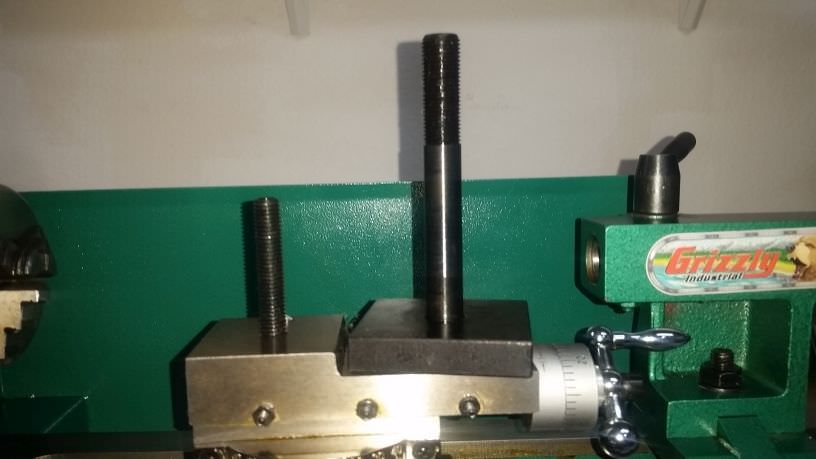

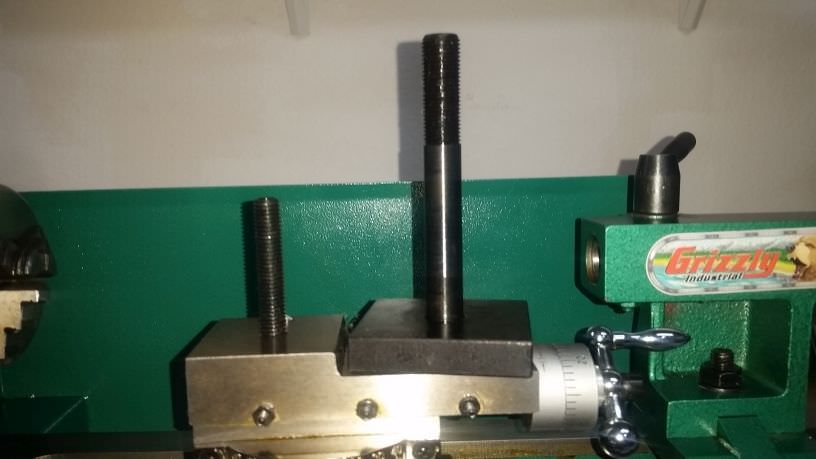

-The AXA Quick Change Tool Post I bought has a bolt that's much larger than the original tool post's bolt. It will not thread into the hole. Do I get rid of that bottom metal plate that came with the new QCTP?

I was thinking either making the hole bigger where the bolt is supposed to thread into or turning the new bolt and then threading it to where the bottom thread will thread into the hole on the bottom. Or just get another piece of round bar and turn and thread it to where it'll fit the new QCTP but thread into the lathe.

-Is there a way to "zero" the dials without a digital one? Like have the tip of your cutting tool touch the outside of your work piece, then zero the dial?

-This is my first ever using a lathe. When I turn the chuck, it seems like it's a tad harder and "rough." I don't know if this is normal or not.

-I bought the 3/8" carbide insert cutters. Which one is which? Which one is for turning, facing, etc.. I know the "E" one is for V grooving.

-The AXA Quick Change Tool Post I bought has a bolt that's much larger than the original tool post's bolt. It will not thread into the hole. Do I get rid of that bottom metal plate that came with the new QCTP?

I was thinking either making the hole bigger where the bolt is supposed to thread into or turning the new bolt and then threading it to where the bottom thread will thread into the hole on the bottom. Or just get another piece of round bar and turn and thread it to where it'll fit the new QCTP but thread into the lathe.

-Is there a way to "zero" the dials without a digital one? Like have the tip of your cutting tool touch the outside of your work piece, then zero the dial?