- Joined

- Mar 22, 2013

- Messages

- 215

Gentlemen,

I thank you for the gracious responses. One of my enjoyments is designing and building engines. The other is sharing it with builders and modelers like you.

That being said here is the next installment in the build.

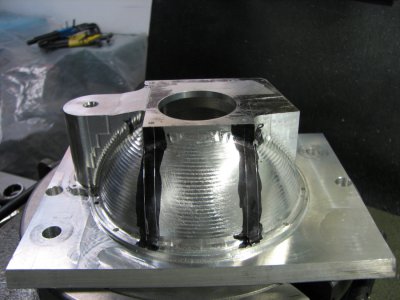

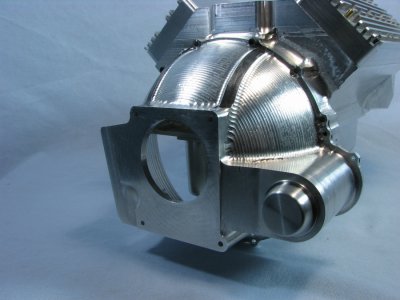

The bellhousing was quite a piece of machining. I start with drawing and metal in hand but have no way of knowing what the time involved will be. I know what my general plan of attack will be but naturally things change as the process gets going.

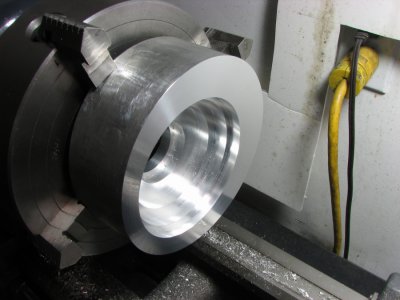

In this case I started with a piece of 6061 aluminum round bar 5.75 inches by 2.25 long. The first step in machining elaborate parts like this or any other is to start with the inside shapes. The reason for this is quite simple. If you machine the outside there is generally no place to chuck or locate to because of the shapes of the surfaces. Once the inside is done you can use a vise, clamps or fixture to do all the outside machining.

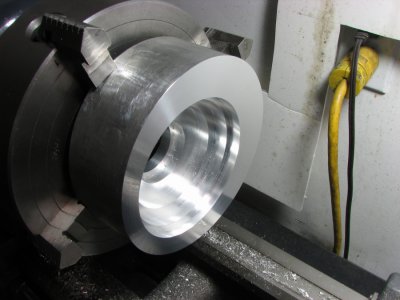

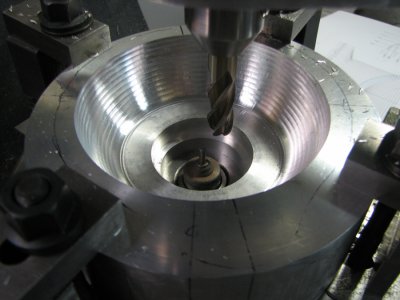

I gave myself some layout lines and chucked the blank in the 4 jaw chuck. Once centered on the layout lines I bored the center hole and then roughed out the extra stock with a heavy boring bar.

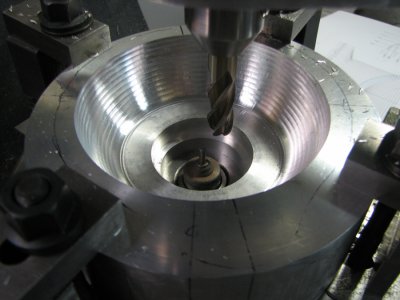

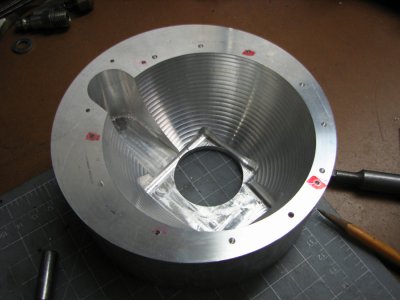

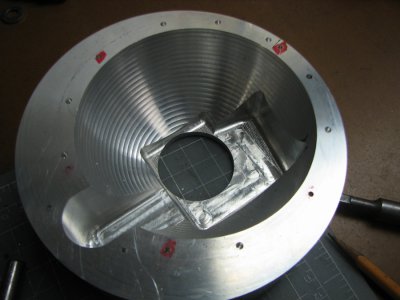

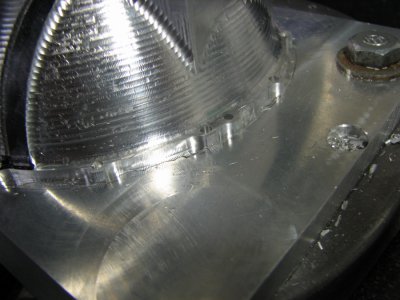

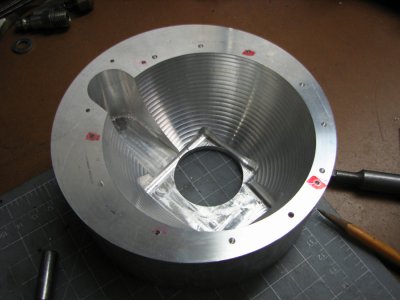

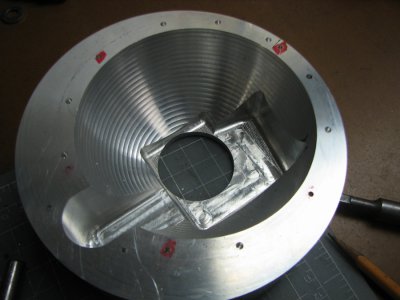

The part was then moved to the rotary table to finish the inside. As with all my contoured parts I make up a step-off chart to form the radii. The rotary table was centered, the zeros set then the part was mounted, centered and clamped. I went in with a .50 diameter ball mill and started stepping off the shape. Once complete I switched over to long 2 flute end mills to cut the inside shape of the clutch area.

I thank you for the gracious responses. One of my enjoyments is designing and building engines. The other is sharing it with builders and modelers like you.

That being said here is the next installment in the build.

The bellhousing was quite a piece of machining. I start with drawing and metal in hand but have no way of knowing what the time involved will be. I know what my general plan of attack will be but naturally things change as the process gets going.

In this case I started with a piece of 6061 aluminum round bar 5.75 inches by 2.25 long. The first step in machining elaborate parts like this or any other is to start with the inside shapes. The reason for this is quite simple. If you machine the outside there is generally no place to chuck or locate to because of the shapes of the surfaces. Once the inside is done you can use a vise, clamps or fixture to do all the outside machining.

I gave myself some layout lines and chucked the blank in the 4 jaw chuck. Once centered on the layout lines I bored the center hole and then roughed out the extra stock with a heavy boring bar.

The part was then moved to the rotary table to finish the inside. As with all my contoured parts I make up a step-off chart to form the radii. The rotary table was centered, the zeros set then the part was mounted, centered and clamped. I went in with a .50 diameter ball mill and started stepping off the shape. Once complete I switched over to long 2 flute end mills to cut the inside shape of the clutch area.