- Joined

- Jan 31, 2012

- Messages

- 212

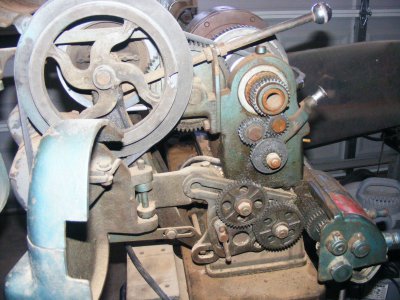

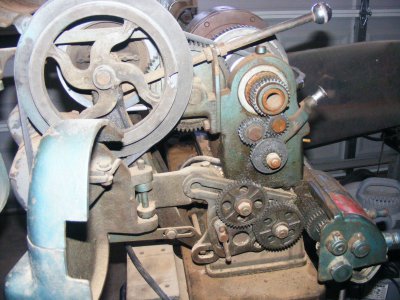

Here she is! I have long been waiting for a lathe.

And it will continue for a while :lmao:

All the grease is literally frozen, most parts have a really sticky motion.

Other than that, the ways are nice, and all the parts are there.

What makes it a good deal is that it came with 3 chucks, a steady rest, all sorts of tool holders and bits, 4 faceplates, 3 Jacobs chucks

(and an unidentified small one on a threaded shank - anyone has seen it before?)

Curious also, in the box I found 3 snap thread gauges. :thinking:

Now the bad news:

I will keep you posted as the renovation starts and progresses.