I’ve been having a little problems with my new vfd install. Aliitle info first. Installed a vfd on my new to me surface grinder. It has a 1hp 220v 3p motor rated at 3450rpm and 2.8amps.

The vfd is a 1p 110v in 3p out 4.3amps.

Wiring went smooth everything went smooth until I went to turn on. Start up went fine but I got OC-A. Reset went to turn on then after about half the rpms I get OC-C.

Initially I read you can’t run off a gfi outlet so I replaced to a standard outlet. No changes. I removed the control circuit and vfd will run motor but when I adjust the hz with the pot I can get it to throw either OC-A or OC-C.

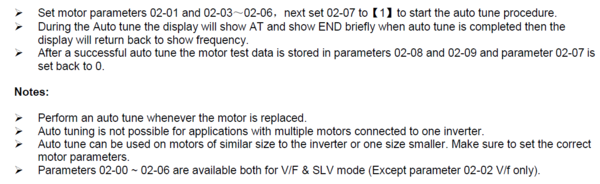

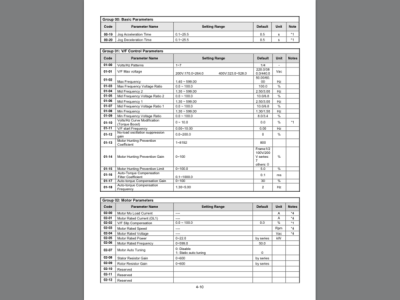

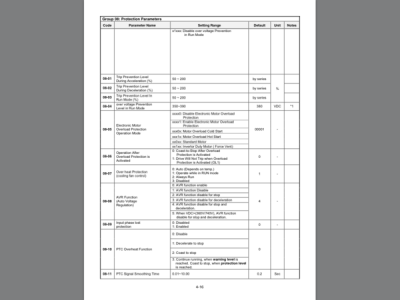

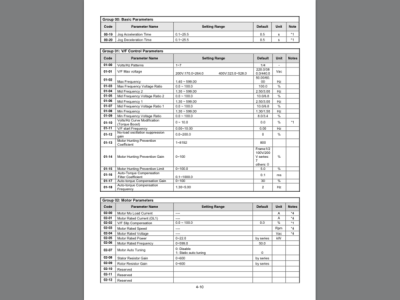

When going through the motor parameters I noticed the vfd is programmed for a 1750 rpm motor. Mine is 3450. Could this be a problem. I really think it’s something to do with programming b cause I can get it to work and throw a code but that’s just on off with slowly moving pot. Anybody have experience with this situation. I’m gonna try calling to supplier. They were helpful on my first install. But I forgot what number I called ?

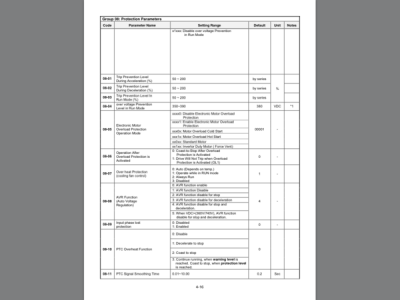

Here’s the programming parameters for a reference any help would be appreciated!!!

The vfd is a 1p 110v in 3p out 4.3amps.

Wiring went smooth everything went smooth until I went to turn on. Start up went fine but I got OC-A. Reset went to turn on then after about half the rpms I get OC-C.

Initially I read you can’t run off a gfi outlet so I replaced to a standard outlet. No changes. I removed the control circuit and vfd will run motor but when I adjust the hz with the pot I can get it to throw either OC-A or OC-C.

When going through the motor parameters I noticed the vfd is programmed for a 1750 rpm motor. Mine is 3450. Could this be a problem. I really think it’s something to do with programming b cause I can get it to work and throw a code but that’s just on off with slowly moving pot. Anybody have experience with this situation. I’m gonna try calling to supplier. They were helpful on my first install. But I forgot what number I called ?

Here’s the programming parameters for a reference any help would be appreciated!!!