This video is on youtube, not sure how to post it here. I did this to my mill and it will line up by alternately tightening the mounting bolts to right at .0005, using a half thou indicator. That's as good as I ever got it the old fashioned way. The video is "A milling machine trick you have to see."

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

A milling machine trick you have to see!

- Thread starter ranch23

- Start date

- Joined

- Apr 12, 2012

- Messages

- 579

Funniest part of the whole video http://www.youtube.com/watch?v=5ISj3Ad4vBU is that the slots for the key was already cut into his vice right along the central bolt holes. Holes below his slot. You do it his way you need to be sure that the key AND the bolts align with the slots or you only can use the vice with clamps.

Pretty much all milling machine vices come slotted for keys and often come with a few common sizes of hardened keys. I like to use keys a bit smaller than the slots which make it easier to get on and off. Simply sliding it around on the table to ensure the keys are against the slot makes it accurate. If extreme accuracy is needed lightly tapping the slightly clamped vice will get it DNO.

Steve

Pretty much all milling machine vices come slotted for keys and often come with a few common sizes of hardened keys. I like to use keys a bit smaller than the slots which make it easier to get on and off. Simply sliding it around on the table to ensure the keys are against the slot makes it accurate. If extreme accuracy is needed lightly tapping the slightly clamped vice will get it DNO.

Steve

My Kurt vises didn't come with keys, didn't know any of them do. The Kurt slots are lined up with the hold down holes, so you can't do that anyway. This works great, have my vise off at least once a week to mount octagon barrel fixture or spacer. A second mill would be the real way to go.

- Joined

- Dec 1, 2010

- Messages

- 1,172

The Kurt that I have, didn't come with keys either. But I made a set up after the purchase . I don't have the swivel base either. I can drop mine on, and with the keys, just push forward, and tighten it snug, and its with in 0.002. With a light tap, its with in 0.0005 It takes all but a minute to get dialed in.

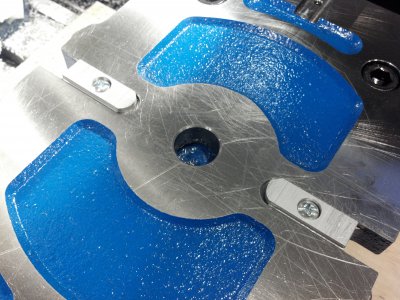

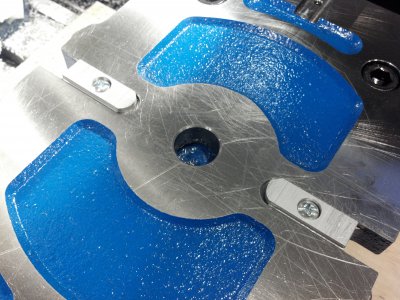

After watching the video and laughing a bit. I decided to make a set for one of my vises. I was able to zero my vise with one tap. The key is getting the slot width correct for the table. My first set I did not account for the difference. with a change to the CNC program I ran off another two. Fits well now. I used some screws I had at the house because the stores were closed for New Years.

Cheers,

-Vince

Cheers,

-Vince

T

Tom Griffin

Forum Guest

Register Today

Here's a little time saving tip of mine for aligning a vise that has a swivel base. It can be applied to a vise without a swivel base as well, as long as it doesn't have keys (especially aluminum keys :huh .

.

Tom

[video=youtube_share;DdgSxoTmtx0]http://youtu.be/DdgSxoTmtx0[/video]

Tom

[video=youtube_share;DdgSxoTmtx0]http://youtu.be/DdgSxoTmtx0[/video]