I finished the base for use on my granite surface plate.

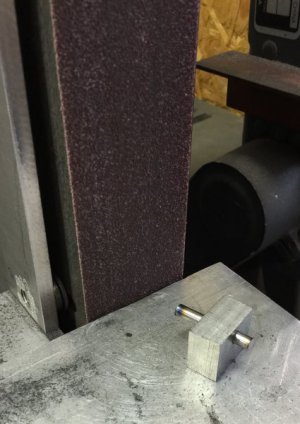

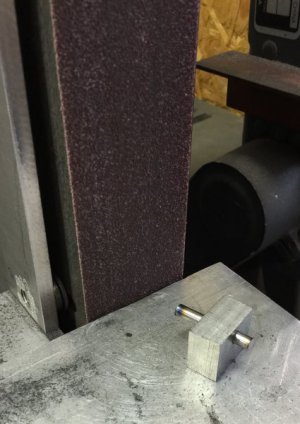

I put a reamed hole in a steel block to hold the push pins square while I ground them.

I put a reamed hole in a steel block to hold the push pins square while I ground them.

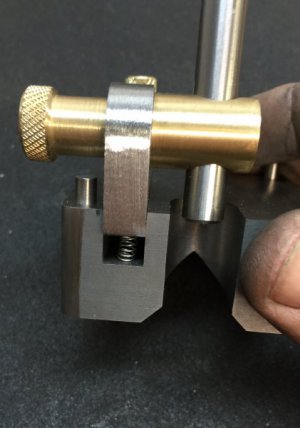

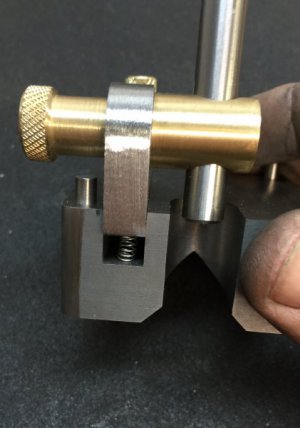

All four push pins are installed.

All four push pins are installed.

I drilled pockets to hold the spring.

I drilled pockets to hold the spring.

The spring is installed. It is the stiffest one I could find. I think it will work just fine. ( the indicator won't overcome it). It is pretty stiff.

The spring is installed. It is the stiffest one I could find. I think it will work just fine. ( the indicator won't overcome it). It is pretty stiff.

Here is the finished base. I will make adapters for the indicators and for a scribe.

Here is the finished base. I will make adapters for the indicators and for a scribe.

Here it is on the granite plate. The mirror finish lets it slide really easy.

Here it is on the granite plate. The mirror finish lets it slide really easy.

I'm going to repeat one more time. With proper use , there is no danger of any damage to the granite plate. I am perfectly satisfied with this project.

I put a reamed hole in a steel block to hold the push pins square while I ground them.

I put a reamed hole in a steel block to hold the push pins square while I ground them. All four push pins are installed.

All four push pins are installed. I drilled pockets to hold the spring.

I drilled pockets to hold the spring. The spring is installed. It is the stiffest one I could find. I think it will work just fine. ( the indicator won't overcome it). It is pretty stiff.

The spring is installed. It is the stiffest one I could find. I think it will work just fine. ( the indicator won't overcome it). It is pretty stiff. Here is the finished base. I will make adapters for the indicators and for a scribe.

Here is the finished base. I will make adapters for the indicators and for a scribe. Here it is on the granite plate. The mirror finish lets it slide really easy.

Here it is on the granite plate. The mirror finish lets it slide really easy.I'm going to repeat one more time. With proper use , there is no danger of any damage to the granite plate. I am perfectly satisfied with this project.