-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

A Straddle Knurler for the Sherline Lathe

- Thread starter mikey

- Start date

- Status

- Not open for further replies.

- Joined

- Mar 12, 2021

- Messages

- 27

Great article, Mikey. The knurling tips will definitely help me make better quality knurls. Most of the time, my knurling goes very well. Though I really think your tips will help me make quality knurls much more consistently. Thanks very much for sharing!

- Joined

- Dec 23, 2019

- Messages

- 176

wow! found this at a perfect time. I didn't even know one could knurl such nicely defined shapes. amazing!!!

- Joined

- Dec 20, 2012

- Messages

- 9,422

wow! found this at a perfect time. I didn't even know one could knurl such nicely defined shapes. amazing!!!

Thank you! With the right tool, knurling is not difficult.

What really sets off a knurl is the treatment on either side of the knurl and the perfect tool to create the shapes you want is a graver. Soft domes, gentle curves or slopes that artistically swoop down to meet the neck of a lever handle are all simple to do with a graver.

- Joined

- Mar 14, 2021

- Messages

- 22

Hi Mikey,

Well written Interesting piece! I just posted my [Hi I’m a GREENHORN & New] & your post got my attention as it mentioned Sherline. In my Intro post I mentioned I have a 4000 series Lathe & purchased it for crafting custom aluminum detail 1:24 scale auto parts- pulleys - tanks- ect.. & went out & bought the Lathe got it set up right - purchased a copy of “Joe Martin’s Tabletop Machining” some 1” & smaller aluminum round stock & then Got (Machine Fright) - just not sure how to start making [Chip’s] ~something like that;-) lol

Any suggestions from a PRO like yourself??

Respectfully,

Lee aka: ZenModeling

Well written Interesting piece! I just posted my [Hi I’m a GREENHORN & New] & your post got my attention as it mentioned Sherline. In my Intro post I mentioned I have a 4000 series Lathe & purchased it for crafting custom aluminum detail 1:24 scale auto parts- pulleys - tanks- ect.. & went out & bought the Lathe got it set up right - purchased a copy of “Joe Martin’s Tabletop Machining” some 1” & smaller aluminum round stock & then Got (Machine Fright) - just not sure how to start making [Chip’s] ~something like that;-) lol

Any suggestions from a PRO like yourself??

Respectfully,

Lee aka: ZenModeling

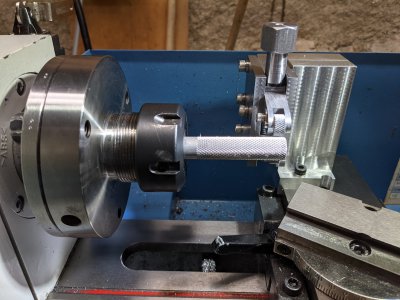

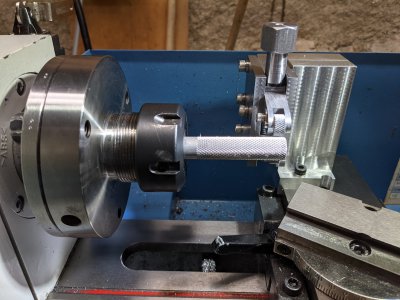

I figured I would post a pic of my build. I think it's a rule around here... I made a couple of changes to use the wheels I already had. Form-Rol KP series. I think I'll order some other pitch and straight versions, but they cut well. I think I needed to go deeper, and I need to practice with it, but the adjustment nut for the knurler turned out alright.

One thing I changed was mounting. I felt like I had too much movement in the QCTP. So I made a block that registers against the plinth. It's probably overkill, but it was interesting to build. I think I'm going to build another block for a more ridgid parting tool holder.

One thing I changed was mounting. I felt like I had too much movement in the QCTP. So I made a block that registers against the plinth. It's probably overkill, but it was interesting to build. I think I'm going to build another block for a more ridgid parting tool holder.

- Joined

- Dec 18, 2019

- Messages

- 6,426

Here's a picture of mine, and a first knurl. (Unsupported 1/2" 6061) I obviously need to make a new nut and knurl it! Haven't quite finished it completely, but wanted to give the knurler a try. The plinth was quite new territory for me, but I came up with something. Had to drill and tap my cross-slide to mount the plinth, but I think it came out ok. I have learned a lot from this little project. @mikey thanks for documenting your build so well. It really helped me understand the thought process in doing something like this. I also want to thank @ttabbal who gave me a couple of helpful hints - they got me out of the corner that I had painted myself into!

- Joined

- Dec 18, 2019

- Messages

- 6,426

@mikey have to ask this. Sorry if it's obvious to everyone. For this knurler, where do the wheels go relative to the stock for best results? I don't recall seeing any description of this. For a bump knurler, one just buts the knurler against the stock. For this kind of knurler, what does one do?

- Status

- Not open for further replies.