- Joined

- Feb 28, 2019

- Messages

- 499

I'm moving to metal work from wood work - although I've got a lot of experience using my Southbend 9 for making mechanical wooden models, I've only done a little metal turning on it.

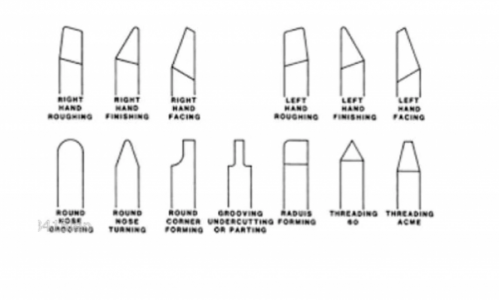

I recently bought a QCTP - mostly because I want to be able to quickly change out cutters and have them setup exactly where I want them when I swap them in. My observation is that a QCTP is almost always setup square to the lathe axis, however, most of the cutter tool geometry descriptions I've seen assume an angled tool approach to the work. (yeah old books).

In the little messing around I've done with my new QCTP, I've already encountered cases where it gets in the way or requires huge unsupported tool bit overhang unless you rotate it.

So none of this is a big deal: geometry wise, if the bit is set square to the lathe, the shape can just be modified to provide that same approach - as if you are coming in from an angle. If the tool post is going to get in the way, then you just rotate it and go back to a profile that works with that approach.

So I'm looking for comments and advise on how people handle this:

- Is there something like a "standard" set of tool shapes to use when the bit is going to be held orthogonal or parallel to the lath axis?

- How often do you find yourself changing the mount angle of your QCTP?

- How often do you use a spotting drill and tail stock support when turning? (this seems to be mostly when the QCTP gets in the way).

I'm sure I'll come to my own preferred work process given enough time and trial.... but would prefer to start with more "common" practice.

- Dave

I recently bought a QCTP - mostly because I want to be able to quickly change out cutters and have them setup exactly where I want them when I swap them in. My observation is that a QCTP is almost always setup square to the lathe axis, however, most of the cutter tool geometry descriptions I've seen assume an angled tool approach to the work. (yeah old books).

In the little messing around I've done with my new QCTP, I've already encountered cases where it gets in the way or requires huge unsupported tool bit overhang unless you rotate it.

So none of this is a big deal: geometry wise, if the bit is set square to the lathe, the shape can just be modified to provide that same approach - as if you are coming in from an angle. If the tool post is going to get in the way, then you just rotate it and go back to a profile that works with that approach.

So I'm looking for comments and advise on how people handle this:

- Is there something like a "standard" set of tool shapes to use when the bit is going to be held orthogonal or parallel to the lath axis?

- How often do you find yourself changing the mount angle of your QCTP?

- How often do you use a spotting drill and tail stock support when turning? (this seems to be mostly when the QCTP gets in the way).

I'm sure I'll come to my own preferred work process given enough time and trial.... but would prefer to start with more "common" practice.

- Dave