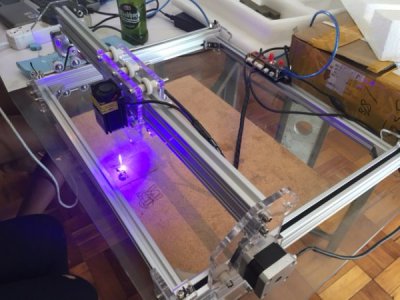

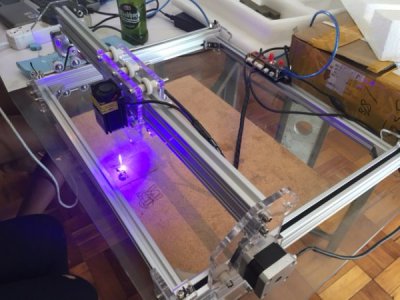

Nice find. This would be great for stencils and gaskets. For metal, you really need the higher peak power of a Q-switched laser. These high peak powers are what allow you to be able to ablate metal. Even the CO2 laser engravers that have maybe 40-50Watts will only engrave metal if a coating is applied to the metal. So it's not really engraving the metal, but rather the coating and some interaction with the metal. Most metal laser engravers that want a direct laser interaction will use a Q-switched fiber laser, YAG laser or similar. The peak powers of these will be in the kW range. Typically also, the beam wavefront or transverse electromagnetic mode are better than nearly all of the multimode diode lasers. This better mode structure allows these lasers to be focused to a very tight beam, increasing the power density.

I used to do a lot of Holography with a 5mW Helium Neon laser. I know 5mW is not much power, but back in the 80's, this laser was $700 and all I could afford. But the beam structure is so clean, it can be focused to a spot that's maybe 10 or 20 microns wide. Even with only 5mW, this laser will burn electrical tape. Just something to keep in mind...

Thanks for sharing your results.

Eric