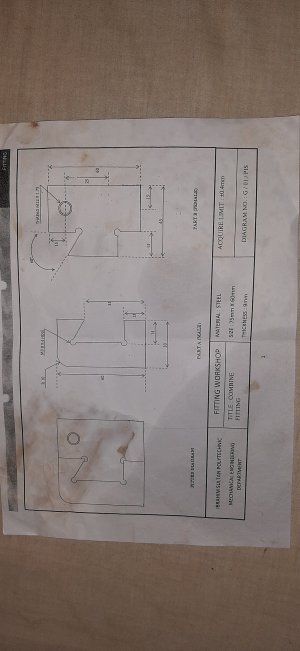

Im currently doing an assignment for workshop class and im curious how accurate can light crack indicate .Im using a caliper's body to indicate uneveness and file it down.Apparently i brought my own equipment to school cuz the ones in the workshop are quite beat up the files are dead smooth and the try square rusting and im not bolting the down the vice as well but shouldnt be a problem since im doing delicate filing for now.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Accuracy of using visual

- Thread starter Koi

- Start date

0.001 sounds unrealistic though is there any evidence to back it up .Depending how good your eyes are down to at least .001 or better.

- Joined

- Sep 13, 2018

- Messages

- 255

You can prove it to yourself by taking a piece of cigarette paper or cellophane, measuring its thickness. Then place the paper at one end between 2 straight items. Shine light from behind.

Last edited:

- Joined

- Feb 9, 2017

- Messages

- 5,243

I would suggest investing in a good machinist square. You have to have at least one truly flat surface. My go to for quite a while was a Starrett 6" rule or blade from a Starrett 6" try square. I kept it in a case and it's original cardboard sleeve so it wouldn't get dinged up. It's great you are next to a window, good light is a necessity. I also avoid tilting a straight edge for checking light unless you try it opposite as it can be slightly bent and give you false readings. Small granite surface plates are fairly cheap and are invaluable for checking your work. The side of a caliper was never meant to be used as a true straight edge IMHO.

Problem for me is after roughing in I do better rubbing the work on the file held on a flat surface than holding the work in a vise and filing it. There is a reason the final step for true flatness is to lap. It's hard to file truly flat. Another truly necessary tool is a set of tool room stones to stone your blade/rule because the slightest ding that you can barely feel will cause all kinds of light between the blade and surface giving another false reading. It's very attainable to get to .001 with very careful attention. But to get beyond that is many times harder.

Problem for me is after roughing in I do better rubbing the work on the file held on a flat surface than holding the work in a vise and filing it. There is a reason the final step for true flatness is to lap. It's hard to file truly flat. Another truly necessary tool is a set of tool room stones to stone your blade/rule because the slightest ding that you can barely feel will cause all kinds of light between the blade and surface giving another false reading. It's very attainable to get to .001 with very careful attention. But to get beyond that is many times harder.

Don bailey shows on surface grinding videos that checking against a know square one can see the light between the part and square will actual turn a blue when within tenths. I personally haven’t done but I trust his word and he does demonstrate in the videos check them out.

I ordered one few days ago and have to go get it tommorow afternoon .Im studying mechatronic for now in a polytechnic and we have workshop assignment fitting i guess not really expecting to do this there though but since i gout the equipments then i might as well just bring it to my dorm.(sounds kinda crazy.I would suggest investing in a good machinist square. You have to have at least one truly flat surface. My go to for quite a while was a Starrett 6" rule or blade from a Starrett 6" try square. I kept it in a case and it's original cardboard sleeve so it wouldn't get dinged up. It's great you are next to a window, good light is a necessity. I also avoid tilting a straight edge for checking light unless you try it opposite as it can be slightly bent and give you false readings. Small granite surface plates are fairly cheap and are invaluable for checking your work. The side of a caliper was never meant to be used as a true straight edge IMHO.

Problem for me is after roughing in I do better rubbing the work on the file held on a flat surface than holding the work in a vise and filing it. There is a reason the final step for true flatness is to lap. It's hard to file truly flat. Another truly necessary tool is a set of tool room stones to stone your blade/rule because the slightest ding that you can barely feel will cause all kinds of light between the blade and surface giving another false reading. It's very attainable to get to .001 with very careful attention. But to get beyond that is many times harder.

Attachments

the vernier is kinda a temporary solution i know it was never meant for the purpose but i didnt know i should not use the sharp edge as a way to see.I would suggest investing in a good machinist square. You have to have at least one truly flat surface. My go to for quite a while was a Starrett 6" rule or blade from a Starrett 6" try square. I kept it in a case and it's original cardboard sleeve so it wouldn't get dinged up. It's great you are next to a window, good light is a necessity. I also avoid tilting a straight edge for checking light unless you try it opposite as it can be slightly bent and give you false readings. Small granite surface plates are fairly cheap and are invaluable for checking your work. The side of a caliper was never meant to be used as a true straight edge IMHO.

Problem for me is after roughing in I do better rubbing the work on the file held on a flat surface than holding the work in a vise and filing it. There is a reason the final step for true flatness is to lap. It's hard to file truly flat. Another truly necessary tool is a set of tool room stones to stone your blade/rule because the slightest ding that you can barely feel will cause all kinds of light between the blade and surface giving another false reading. It's very attainable to get to .001 with very careful attention. But to get beyond that is many times harder.