- Joined

- Mar 3, 2014

- Messages

- 634

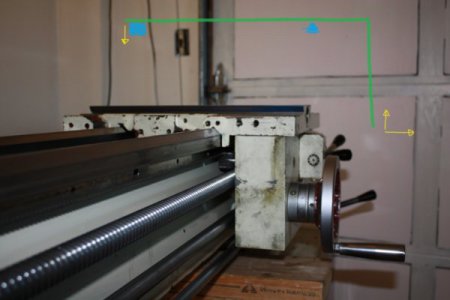

Have a couple problems so far though I've only just started working on it.

First, the gap seems to have a soft foot. What surprised me is that the bottom of the gap and the seat were completed with a disk grinder.

Thought I could expect more from Acer.

I have yet to fully re-install the gap so perhaps no change will be required, however, could anyone tell me if they've seen this before and what is the procedure to correct it.

My other problem is more of a decision I'm reluctant to make.

Here is the bottom of the saddle before I've touched it.

Nice job Acer! We've got at least 90% contact. NOT!

Nice job Acer! We've got at least 90% contact. NOT!

Well, I can deal with that though getting the saddle set square to the spindle is a try and true effort till it's rite sorta thing with me.

Took about six adjustments on my little lathe till it was rite.

The real problem/decision is that the saddle is about 19 thousanths high on the inboard side. Yea, it's about 0.002"/ inch from rail to rail.

Now that I have my little mill/drill cutting square and flat. I could machine the majority of the material and scrape it in. Just not certain if it's worth the effort.

Would like your input of the pro's and cons.

First, the gap seems to have a soft foot. What surprised me is that the bottom of the gap and the seat were completed with a disk grinder.

Thought I could expect more from Acer.

I have yet to fully re-install the gap so perhaps no change will be required, however, could anyone tell me if they've seen this before and what is the procedure to correct it.

My other problem is more of a decision I'm reluctant to make.

Here is the bottom of the saddle before I've touched it.

Nice job Acer! We've got at least 90% contact. NOT!

Nice job Acer! We've got at least 90% contact. NOT!Well, I can deal with that though getting the saddle set square to the spindle is a try and true effort till it's rite sorta thing with me.

Took about six adjustments on my little lathe till it was rite.

The real problem/decision is that the saddle is about 19 thousanths high on the inboard side. Yea, it's about 0.002"/ inch from rail to rail.

Now that I have my little mill/drill cutting square and flat. I could machine the majority of the material and scrape it in. Just not certain if it's worth the effort.

Would like your input of the pro's and cons.