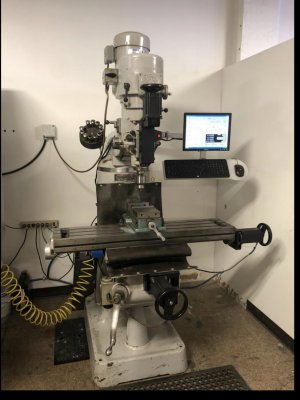

Hello, I just purchased a Alliant mill with a CNC masters controller on it. Let me first explain something, I am not a machinist. I am just getting into this as a hobby. This is my first machine. This retrofit was done in 06. I am currently exploring how difficult it would be to upgrade this controller to a acorn. I would like to keep the stepper motors for now. I want to keep the upgrade as cheap as possible for now. I want to learn how to use the machine before doing a full upgrade with servo motors. I contacted centroid about the upgrade and was told the acorn works with stepper motors but they weren’t sure if or how the existing motor drives would be wired. There is no documentation on the drivers or motors. I am just looking for someone who has done this or knows how I would adapt the acorn to my drivers/motors. I will post some pictures of what I have.

Any input would be greatly appreciated!

Any input would be greatly appreciated!