Hi,

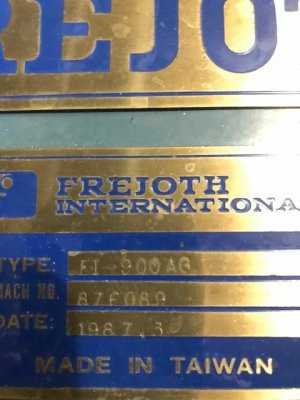

I am afraid the Mens Shed I attend recently purchased an Acraturn FI-900ag/e lathe. This lathe is quite close to the one shown in the manual posted in this thread. The lathe appears to have done very little work but has corrosion pitting due to neglect, I have a theory as to why it has seen little work, more on this later. The bed, headstock, quick change gearbox and tailstock appear to be the same as the manual. The apron is probably the same, externally it appears the same. The saddle is similar but not identical. Unfortunately the cross slide and compound are different. The cross slide has a very different and very BADLY DESIGNED nut system. The compound is similar to but not the same as the one in the manual.

This lathe is clearly a hybrid made up of parts supplied by different manufacturers, the variations in quality and finish are stark!

The headstock, quick change box and bed appear to be reasonably well-made, although I have not had the chance to run a test indicator over the bed. When it was purchased, the oil had leaked below the level visible in the bubbles, the viscosity of the oil was far too high, it was discoloured and stank, it had clearly been overheating. I spent some time working out and then double checking the correct grade of oil for the gearboxes at ISO32, the manual from here confirms my calculations, phew, got something right. The gearboxes are still noisier and run hotter than what I would like.

The tailstock is, well, serviceable, that is the best I can say, it is afflicted with corrosion due to low grade materials and finish, operation is okay but nothing to write home about.

The jury is out on the apron, it could be okay but without a far more detailed survey (disassembly required), I can't say.

The saddle is nowhere as well made as even the tailstock. It is clearly cast from inferior metal (significant deep pitting showing a course grain cast iron) and there is a large casting flaw right in the middle of one of the ways for the cross slide! The slide ways for the saddle, cross slide, and compound are all just rough (and I mean rough!) machined, there is not a decent surface on any of them. The gibs are not machined at all and have a rough surface from their forming (and hardening?) processes. There is no way of oiling the cross slide nuts or the slideways properly, no ball oilers or oilers of any kind anywhere on the cross slide.

The steadies appear to be reasonably okay with mostly surface rust, they look the same as all their other contemporaries and could have come from the same factory. I have not been able to properly inspect the 3 jaw chuck as someone has taken it home for some strange, unknown reason (same with the compound). The four jaw chuck seams to be of reasonable quality and virtually unused, I have not tested its runout etc. The reason for this oversight is due to the chuck backing plates not being properly machined!!! They are again a rough surface that shows some preliminary machining before some other process have altered the surface finish, they were never reground to specifications. Neither the registration cone nor the registration surface contact the nose of the spindle with more than about 2% of their surfaces - just touch with the odd high spot. I assume that in order to try and get a higher gripping force between the spindle nose and chuck backing plate, the previous owner has maladjusted the cam locks, they are way outside their proper tightened zone. The cam lock pins are also showing damage due to transverse forces (slippage between chuck and spindle nose), clearly the cam lock pins are seeing significant shear forces. The registration cone of the spindle nose is also showing signs that the chuck is moving transversely while rotating. The registration surface that mate to the chucks are in the same condition. The faceplate, don't go there! The whole thing is a nightmare and I find it scary that anyone would use it in this state, let alone sell it.

So, onto the piece de resistance of this gothic novel, the cross slide nut(s). The cross slide has two nuts (probably soft brass - doesn't look like bronze to me), widely spaced with a tapered set screw to push them apart in order to reduce backlash, it is a pity that neither of the nuts comes anywhere near to the adjustment set screw. Not that it matters, as they are mounted in such a way that that cannot move relative to one another. At some stage they were clearly poorly aligned and have been forced along the screw resulting in large amounts of wear. The nuts are only engaging part of the screw as the major and minor diameters of the nut thread are too large. The nut is too small resulting in there only being a few thousandths of an inch of brass between the major and the bottom of the nut, forces have obviously (calipers) expanded the inadequate nut adding to all its other woes. The whole nut system needs to be redesigned to a more conventional solution with one adjustable nut. Just to add further, the cap head machine screws holding the nut to its support are far too short, I do not know how they have not torn out.

So, why such little use, simple, it is essentially unusable.

Just to add insult to injury, this lathe was purchased (with an equally suspicious benchtop milling machine) to replace an almost complete, 1943 South Bend 9A lathe that the shed had acquired for free and that I had spent many hours (and quite a bit of my own personal dollars) getting back to proper running order (the previous owner was obviously allergic to oil, grease in the saddle and gearbox, ways as dry as, - urggghhh), it was quite capable of doing most of what the shed would have required (worn - not too badly - but not broken), I had planned to fully restore it to perfect, within tolerance, working condition. However, the South Bend was then sold over my strenuous and continuous objections, not least because the Acraturn had not been run and was unproven (never sell your current runner before its successor is proven), currently the shed does not have a working metal lathe, has not had one for weeks nor does it appear to be having one for some time. Oh well, back to my first love, woodwork using hand tools.

From an emotional point of view, this is like selling your prized vintage car to replace it with an, old, Great Wall ute. The funny part is that I was told getting the Acraturn was to try and be more attractive to metal workers! So, what is more interesting, seeing just how much you can get out of a small vintage lathe, or working with yet another piece of anonymous Chinese ... Oh yes, I can get most any part I want for the Southbend (either Southbend or Hercus sourced), Acraturn? hahahaha

Where am I located? All I will say is that I am in South East Queensland.

In summary, Acraturn FI-900ag/e = POC

Southbend ruled (new owner, very happy indeed - it grew on him just as fast as it grew on me)

If you are still reading, thanks for putting up with my rant.