- Joined

- Jan 22, 2020

- Messages

- 42

I'm looking for any pics that you guys might have of your DIY / home made adjustable motor mounting bracket please.

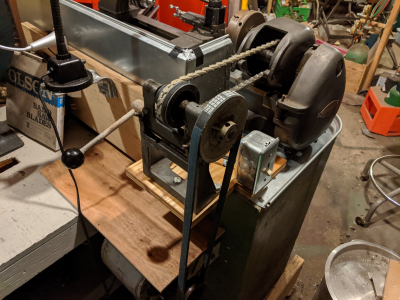

I have a Craftsman 101.0730 with the early L9-20A counter shaft bracket...….the early version with the "three holes" in the base. I'm in the process of mounting the motor and the counter shaft bracket, based on the ?correct? V belt length, to the poorly made bench that came with the lathe. This bench will suffice for the time being.

On that note...….I would like to make adjustable mounting brackets for both the motor and the counter shaft bracket, so I can tension these belts individually and independently of each other. Looking to be able to go up or down in belt length an inch or so at least, from the current belt lengths I have now. Currently, the motor sits on a door hinge, and bounces around under it's own weight, when in use. This poorly thot out design will not be re-implemented, for sure.

Anyone have pics to share please, for ideas?

I have a Craftsman 101.0730 with the early L9-20A counter shaft bracket...….the early version with the "three holes" in the base. I'm in the process of mounting the motor and the counter shaft bracket, based on the ?correct? V belt length, to the poorly made bench that came with the lathe. This bench will suffice for the time being.

On that note...….I would like to make adjustable mounting brackets for both the motor and the counter shaft bracket, so I can tension these belts individually and independently of each other. Looking to be able to go up or down in belt length an inch or so at least, from the current belt lengths I have now. Currently, the motor sits on a door hinge, and bounces around under it's own weight, when in use. This poorly thot out design will not be re-implemented, for sure.

Anyone have pics to share please, for ideas?