- Joined

- Jun 21, 2020

- Messages

- 26

Following up on my intro post here: https://www.hobby-machinist.com/threads/my-first-new-to-me-lathe.85003/

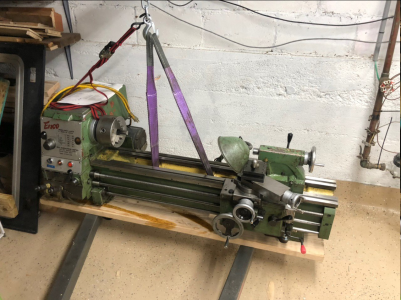

I'd been searching craigslist for a while for a decent lathe frame and this 1980 Enco 92030 popped up for $600 and jumped at the opportunity. Included a fair bit of parts, 3 jaw, 4 jaw, drill chuck, dead centers, live centers, etc. Not really any tooling but with the tool post will fit up to 5/8" so I grabbed some HSS tools to get started.

It was pretty grimy when I got it so I decided to clean up as much as I could easily access before bringing it in the house. Here's some pictures from the listing:

Getting it through my bulkhead was very precarious. I need to figure out some sort of hoist setup to make lowering heavy pieces into the basement more safely, but the engine lift did it's job.

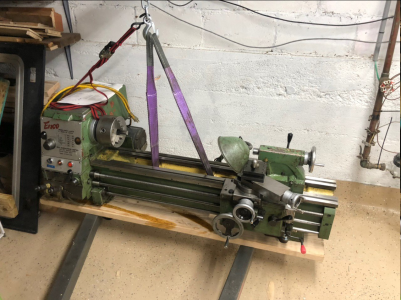

And here it is on it's way to it's new home.

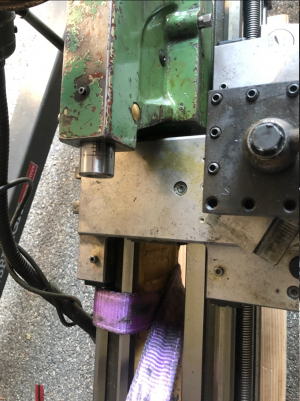

Table cleaned and assembled:

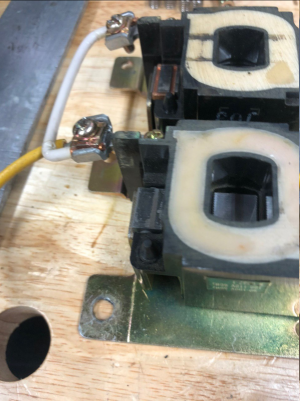

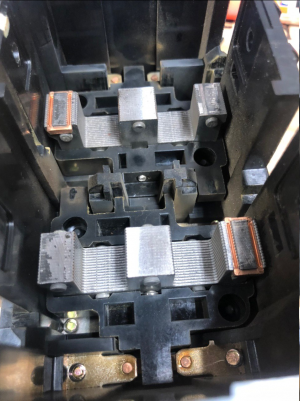

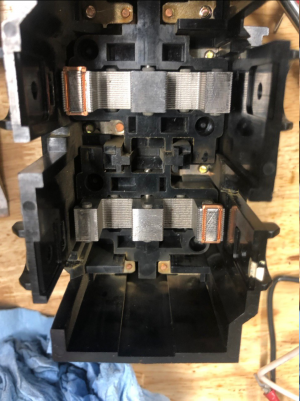

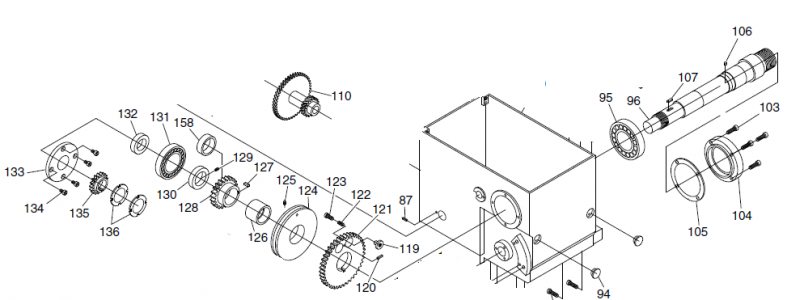

Finally bolted back in place. The speed control setup is still pretty grimy and the gearbox is full of belt wear chunks, but that's a problem for future me.

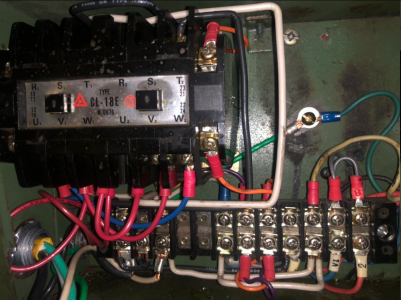

With it home it's time to start getting it running...

I'd been searching craigslist for a while for a decent lathe frame and this 1980 Enco 92030 popped up for $600 and jumped at the opportunity. Included a fair bit of parts, 3 jaw, 4 jaw, drill chuck, dead centers, live centers, etc. Not really any tooling but with the tool post will fit up to 5/8" so I grabbed some HSS tools to get started.

It was pretty grimy when I got it so I decided to clean up as much as I could easily access before bringing it in the house. Here's some pictures from the listing:

Getting it through my bulkhead was very precarious. I need to figure out some sort of hoist setup to make lowering heavy pieces into the basement more safely, but the engine lift did it's job.

And here it is on it's way to it's new home.

Table cleaned and assembled:

Finally bolted back in place. The speed control setup is still pretty grimy and the gearbox is full of belt wear chunks, but that's a problem for future me.

With it home it's time to start getting it running...