Had a change of heart partway through the day. Canceled the shipment for the motor and I'm going to see what I can figure out first. Then I tried canceling the mcmaster pulley but I guess they're sending it anyways and don't want it back. Thanks guys.

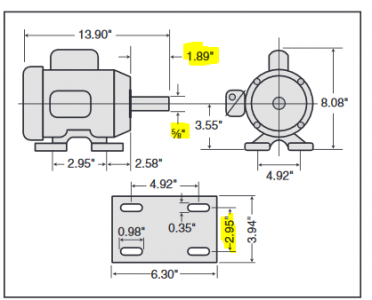

I see now that the previous owner had faced off a similar 3 step pulley to make it fit, hence why it was a 4" and 3". I'm tempted to just buy the motor and pulley for the grizzly g9249 but there's no documentation on it so it's a guess if it will fit. Need to see what other options there are.

I got the back gear apart after some coercion of the oil bushings to see about the fitment on the back gear. Definitely not going to fit. The grizzly is a 58x21 and I counted that the large gear on my back gear is 52. I don't know for certain what the small gear on the original backgear was, but I'm guessing 21 by how close the 22 came to fitting. This led me to a Jet 3211 series lathes which uses a backgear that looks about the same, but the only place I found it was this store that seems a bit questionable:

https://www.toolpartspro.com/jet-parts/jet-321110-parts/jet-04109a-gear

View attachment 332577

The small pinion on the grizzly was rubbing into the pulley at best.

View attachment 332579

The big buy wouldn't have fit at all

View attachment 332580

Here you can see the obvious size difference:

View attachment 332581

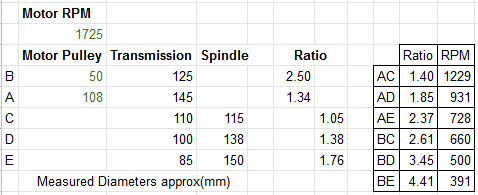

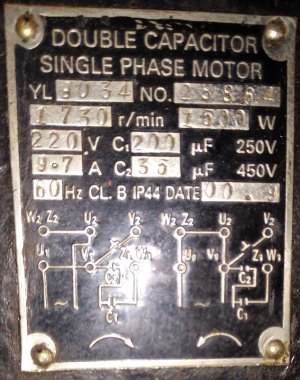

If anyone has any opinions between buying a cheap 1 phase VFD from china or swapping for a correct 1725RPM motor I'd be interested in hearing them.

Mike