- Joined

- Nov 17, 2012

- Messages

- 48

I am dipping my toes in the waters of machining as a part-time gig. My focus for now will be small jobs from Xometry. I know people have strong opinions about Xometry, but it's the decision I've made that's best for me and my current goals.

If you were starting a small, one-person, side-gig CNC machining business in your garage, what machine would you choose? Please keep in mind that my budget is somewhere in the $16k range.

My options are :

- A new PCNC 440 with some extras.

- A new 770M with very limited extras.

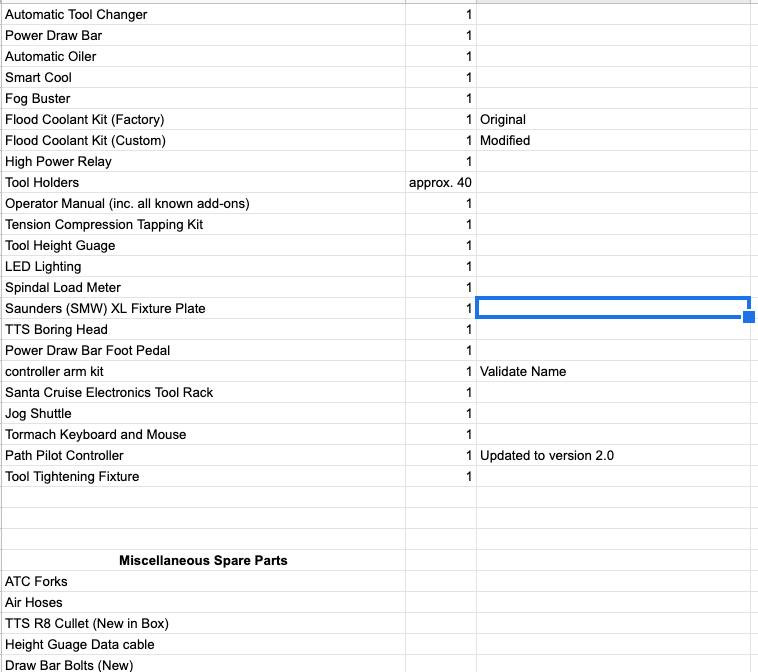

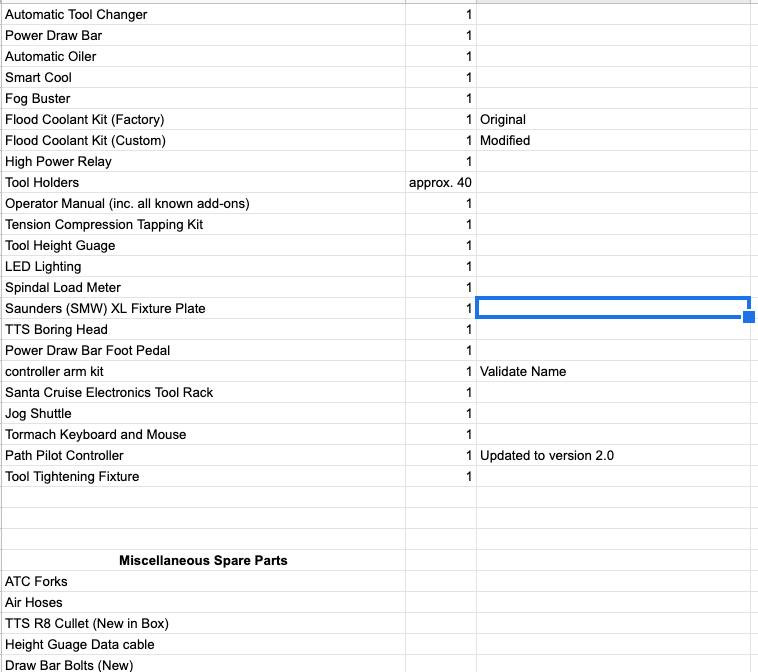

- A used PCNC 1100 with lots of extras, for a great price that is pushing my budget a little, but well below $20k. Below is a list of what comes with the used PCNC 1100.

Here's a little about me. I'm a tech nerd. I'm in my 36th year as software engineer. I love Fusion 360. I'm finishing off a Fusion 360 deep-dive course. In October, I head to Saunders Machine Works (DIY CNC) for his Hands On CNC Machining Training Class. I already own and work on a manual lathe and milling machine.

Thanks!

Chris

If you were starting a small, one-person, side-gig CNC machining business in your garage, what machine would you choose? Please keep in mind that my budget is somewhere in the $16k range.

My options are :

- A new PCNC 440 with some extras.

- A new 770M with very limited extras.

- A used PCNC 1100 with lots of extras, for a great price that is pushing my budget a little, but well below $20k. Below is a list of what comes with the used PCNC 1100.

Here's a little about me. I'm a tech nerd. I'm in my 36th year as software engineer. I love Fusion 360. I'm finishing off a Fusion 360 deep-dive course. In October, I head to Saunders Machine Works (DIY CNC) for his Hands On CNC Machining Training Class. I already own and work on a manual lathe and milling machine.

Thanks!

Chris

Last edited: