You'll get a sense of how much it costs when you're finished. Not before.With above - I can get a sense of Phase I and Phase II major component costs/ configurations.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Advice on Bridgeport converted to CNC for sale

- Thread starter Charlieman22

- Start date

- Joined

- May 2, 2021

- Messages

- 330

So these would be a config that would require addition of a BOB - where the Galil would be an all in one, and a single Galil like the 4140 would be the motion control for all of my servos.All three of the devices I linked to earlier fall in to the "SERVO DRIVE" category, not the motion controller or BOB category.

Looks like Galil holds tight distribution rules.

I'll contact to get pricing info.

Ralf - For one's falling into Servo Drive category - requiring BOB - would I need 1 Drive per servo or does 1 Drive box handle multiple servos also? That part still a bit fuzzy for me.

Thanks - yes.Maybe a diagram will help.

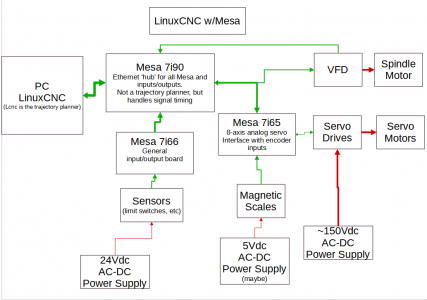

Green arrows are information or signals. Red is power.

Got it! Thanks! This is the stripped down version. My inclination is to consider finding a smaller box to put on the side or back to keep things tidy until I figure out how I will configure the entire thing.AC in > master disconnect switch > fuse/breaker > contactor > VFD > motor

Not that it's make or break - but still curious about this. Jim - did your thinking about best config for me evolve making these obsolete?1. When I first posted the pic of the box with numbers on sections - #2 was Servo Drives.("need some slight modification"). Would the Galil or Copeley mean these would get tossed rather than kept? (did this plan change?)

Lotta time put in by you guys on this.

I'm now armed and unquestionably dangerous - most likely to myself.

I will craft my build thread.

Current working title: Beauty in The Beast.

-CM

- Joined

- Feb 8, 2014

- Messages

- 11,144

Ralph's description/diagram above is beautiful. Shows all of the components required to make a professional CNC system and how they interact with each other.

So the plan at this point:

Closed loop system, loop closed at the controller, no real point in discussing the other options.

The brain of the system is the motion controller. This could be Galil, Dynomotion, Centroid, or Mesa.

PC running the CNC software and providing the user interface. In this case would be connected to the controller via Ethernet or USB cable.

One drive required for each axis motor (3), compatible drives currently exist in the machine. Ignore the fact that Galil does have optional built in servo drives available.

Position feedback devices (encoders) can be linear or rotary. Recommend linear magnetic. One for each powered axis (X, Y, Z (quill)), plus the knee. (4)

Appropriate power supplies to run everything.

If you are going to go with a Galil, a DMC-4040 4 axis unit from eBay would be my choice. The last DMC-4040 I bought was $112, retail price is $2295 for the base unit from Galil. A fully loaded DMC-4040 with 4 built in 160V, 750W drives is $3530. Stay away from the 41x3 units.

Just a bit of clarification, a BOB is just simply a Break Out Board, something to connect wires to (normally with screw terminals), since it would be difficult to solder wires directly to the controller chip. The controller manufactures bring out the connections on the controller board to some type of plug connectors or screw terminals. Galil for instance uses D-sub connectors on their units, there are many options available to break those out to screw terminals.

An example: https://www.amazon.com/D-SUB-Terminal-Breakout-Connector-Screws/dp/B0779WGQN4

So the plan at this point:

Closed loop system, loop closed at the controller, no real point in discussing the other options.

The brain of the system is the motion controller. This could be Galil, Dynomotion, Centroid, or Mesa.

PC running the CNC software and providing the user interface. In this case would be connected to the controller via Ethernet or USB cable.

One drive required for each axis motor (3), compatible drives currently exist in the machine. Ignore the fact that Galil does have optional built in servo drives available.

Position feedback devices (encoders) can be linear or rotary. Recommend linear magnetic. One for each powered axis (X, Y, Z (quill)), plus the knee. (4)

Appropriate power supplies to run everything.

If you are going to go with a Galil, a DMC-4040 4 axis unit from eBay would be my choice. The last DMC-4040 I bought was $112, retail price is $2295 for the base unit from Galil. A fully loaded DMC-4040 with 4 built in 160V, 750W drives is $3530. Stay away from the 41x3 units.

Just a bit of clarification, a BOB is just simply a Break Out Board, something to connect wires to (normally with screw terminals), since it would be difficult to solder wires directly to the controller chip. The controller manufactures bring out the connections on the controller board to some type of plug connectors or screw terminals. Galil for instance uses D-sub connectors on their units, there are many options available to break those out to screw terminals.

An example: https://www.amazon.com/D-SUB-Terminal-Breakout-Connector-Screws/dp/B0779WGQN4

- Joined

- May 2, 2021

- Messages

- 330

Well - it's appropriate that Jim made the final post in this - for the time being.

And an excellent last bit of info it is.

Thank you.

New thread on the heavy lifting and rehab of the physical machine starts here:

www.hobby-machinist.com

www.hobby-machinist.com

Thanks to all who helped me get launched to this point.

Come join the group helping or throwing tomatoes at me over at the other post!

-CM

And an excellent last bit of info it is.

Thank you.

I will set alerts to let me know if one pops up while I work on the physical machine in the mean time. Let's see if a 4040 shows up. This is my target.If you are going to go with a Galil, a DMC-4040 4 axis unit from eBay would be my choice. The last DMC-4040 I bought was $112, retail price is $2295 for the base unit from Galil. A fully loaded DMC-4040 with 4 built in 160V, 750W drives is $3530. Stay away from the 41x3 units.

New thread on the heavy lifting and rehab of the physical machine starts here:

Beauty in The Beast: Webb 5BVK Barn Find/Conversion

New to forum & machining generally. Working on two stroke motors drove my initial interest to learn. Started searching for a Bridgeport... Next thing I knew - I was standing outside a barn, 2 hours from my house, looking at a 4K lb non working CNC Webb knee mill. More about how I got there and...

www.hobby-machinist.com

www.hobby-machinist.com

Thanks to all who helped me get launched to this point.

Come join the group helping or throwing tomatoes at me over at the other post!

-CM

[blush]Ralph's description/diagram above is beautiful.

To expand on Jim's description of the BOB... remember that the diagram I drew identifies various functions - not just specific components. In some systems those functions are combined in to a single device; in others the functions are split up. I drew that one as it was as close as I could get to a Galil-based system (not having used one before).

The big dividing point (in my mind) is what device is planning the trajectory of each axis? The 'thing' that does the trajectory planning is not always as I've drawn it; the lines blur depending on what software or hardware you're using. That's why I labeled the Galil as 'motion controller', with the BOB function as a sub-set within the box.

Here's a different example with LInuxCNC and a Mesa setup for analog servos. LinuxCNC is the trajectory planner/motion controller, but the main Mesa board is more than just a breakout board. It takes commands from the PC and generates very precise signals to the drives, as well as acting as a 'hub' for other components (like encoders, general sensors, etc.)

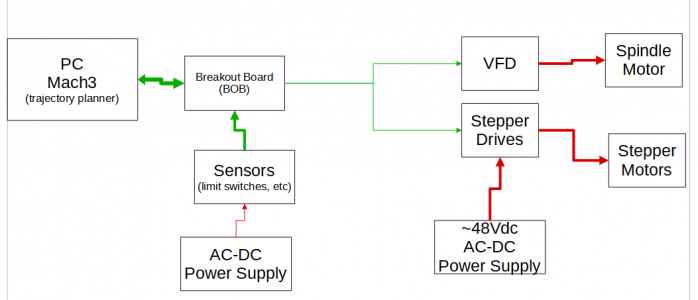

Last is the most simplistic system. PC with Mach3, connected to the various stuff through a 'dumb' break out board like Jim described:

This one has no feedback from the drives to Mach3. Mach3 has no idea what's going on, except for the various limit switches and similar. No encoders, no analog servo drives. Just stepper motors.

There are many, many different configurations than the three I've drawn out for you, but hopefully you get the gist of general architecture.

-Ralph