- Joined

- Mar 19, 2015

- Messages

- 275

i have a pce of 1" thick 5.25" ish rd ali, i used it to make chuck backing plate for my 4 jaw independant chuck.

did it when first got lathe and a bit to eager.

needless to say its not right .

the holes and register to fit my lathe are right but front is wrong, was wondering if i faced it off could i use it as a sacrificial faceplate?

got some holes to bore out on end of some flat strip.

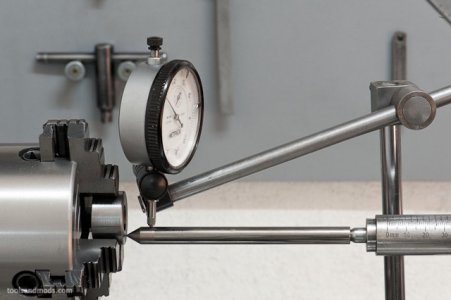

to center bar on chuck can i use centre in tailstock bring it up to snug fit in hole then clamp strip up tight?

got shown how to mark out holes properly at model eng club other day using rotary table on mill.

then got me to make adaptor for something he is building and i got it right.

sorry for being long winded.

did it when first got lathe and a bit to eager.

needless to say its not right .

the holes and register to fit my lathe are right but front is wrong, was wondering if i faced it off could i use it as a sacrificial faceplate?

got some holes to bore out on end of some flat strip.

to center bar on chuck can i use centre in tailstock bring it up to snug fit in hole then clamp strip up tight?

got shown how to mark out holes properly at model eng club other day using rotary table on mill.

then got me to make adaptor for something he is building and i got it right.

sorry for being long winded.