- Joined

- Dec 22, 2015

- Messages

- 561

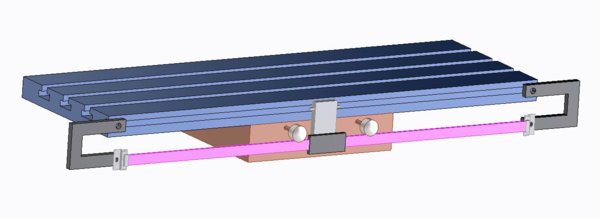

I just got this new Align 500D power feed and installed it on my mill drill. It took quite a bit of alterations to the mounting for the power feed auto shut off switch and for the DRO but I got it done.

I have a concern about the operation though. When I control the power feed by hand and stop it with the direction lever, it stops immediately. However when I use the stop limit switch to control the movement limits, the table coasts to a stop, it does not stop immediately. The coast distance varies with the travel speed and can be quite a bit. This doesn't make sense to me. If this is normal how would the limit switch be used when cutting a slot? Is this normal or is there something wrong with this machine? It seems silly to me that it would not stop immediately.

I have a concern about the operation though. When I control the power feed by hand and stop it with the direction lever, it stops immediately. However when I use the stop limit switch to control the movement limits, the table coasts to a stop, it does not stop immediately. The coast distance varies with the travel speed and can be quite a bit. This doesn't make sense to me. If this is normal how would the limit switch be used when cutting a slot? Is this normal or is there something wrong with this machine? It seems silly to me that it would not stop immediately.