- Joined

- Jan 22, 2022

- Messages

- 128

Full disclaimer… I’m a big machining amateur.

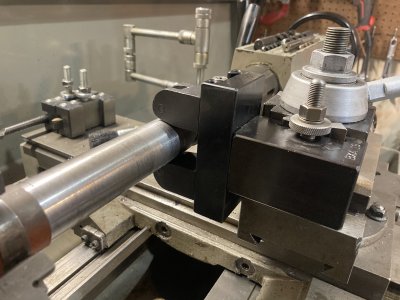

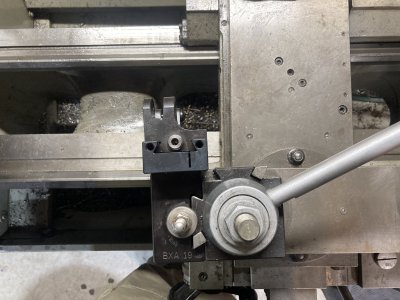

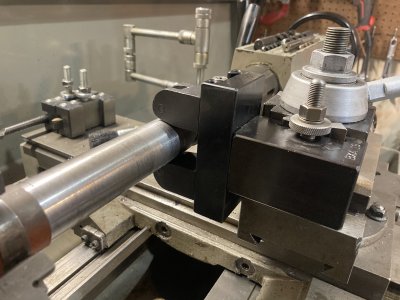

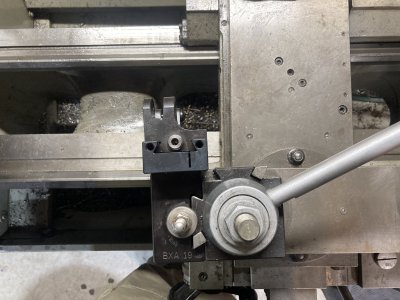

I was excited to receive my BXA-19 from eBay today. I had previous “success” in the past on my Atlas 12” with an Amazon scissor knurling tool.

I quickly slapped it on my lathe. Lined it up good enough and had at it. It was doing ok for a while then it got jammed up. I noticed one of the suppled knurls (Accu Trak 25 TPI) had a chip. That was there before I started.

When I say jammed up it slightly moved the QCTP, started smoking and destroyed the knurling it was making.

So I took the knurls out and put in some Chinese made knurls. Again, ran ok but then jammed up.

What’s my most likely problem here? I haven’t yet leveled my lathe. I’m pretty sure it needs adjustment. The BXA-19 appears fully functional without anything broken or missing. I’m really hoping I didn’t just waste $200 on a broken BXA-19.

My gut tells me my bed isn’t straight because it’s not leveled. That’s why it will go about 2-3 inches fine then it fails. My second guess is I’m just doing something wrong.

I did order two new sets of knurls and a replacement screw from Aloris. While I’m waiting for those to arrive I should probably research the proper way to do knurling.

I also had to set my compound up in a 90 degree angle. It was the only way I could use the BXA-19 on my lathe. I can’t find a user manual for the BXA-19. Can any one help me?

I was excited to receive my BXA-19 from eBay today. I had previous “success” in the past on my Atlas 12” with an Amazon scissor knurling tool.

I quickly slapped it on my lathe. Lined it up good enough and had at it. It was doing ok for a while then it got jammed up. I noticed one of the suppled knurls (Accu Trak 25 TPI) had a chip. That was there before I started.

When I say jammed up it slightly moved the QCTP, started smoking and destroyed the knurling it was making.

So I took the knurls out and put in some Chinese made knurls. Again, ran ok but then jammed up.

What’s my most likely problem here? I haven’t yet leveled my lathe. I’m pretty sure it needs adjustment. The BXA-19 appears fully functional without anything broken or missing. I’m really hoping I didn’t just waste $200 on a broken BXA-19.

My gut tells me my bed isn’t straight because it’s not leveled. That’s why it will go about 2-3 inches fine then it fails. My second guess is I’m just doing something wrong.

I did order two new sets of knurls and a replacement screw from Aloris. While I’m waiting for those to arrive I should probably research the proper way to do knurling.

I also had to set my compound up in a 90 degree angle. It was the only way I could use the BXA-19 on my lathe. I can’t find a user manual for the BXA-19. Can any one help me?

Attachments

Last edited: