-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Alternative motor?

- Thread starter Olddaddy

- Start date

- Joined

- May 10, 2014

- Messages

- 819

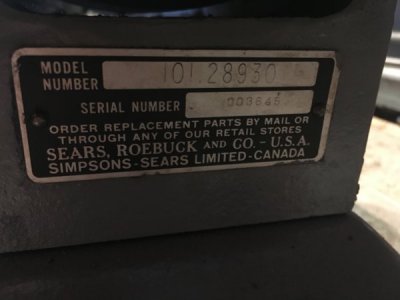

That is a standard NEMA Frame 56 1/2HP 1725 rpm. You should be able to find replacements on EBay, internet sites, a local Tractor Supply or Harbor Freight.

One example internet site

DealersElectric 1/2HP motors

One example internet site

DealersElectric 1/2HP motors

- Joined

- Dec 25, 2011

- Messages

- 10,511

It will be more expensive as at least the last two that I bought there still claimed to be US made, unlike anything that you would get from HF. But WW Grainger will also have several choices. If you do buy a new or good used one, make very sure that if it has a thermal overload breaker, it is manual and not automatic reset. The automatic reset type is dangerous and can kill or maim you if you don't take the proper precautions (basically unplugging the machine before you touch anything if it ever trips.

But as Eddy said, there are several things that can go wrong with a capacitor start motor that are relatively easy to fix and not as expensive as buying a new or used replacement motor.

But as Eddy said, there are several things that can go wrong with a capacitor start motor that are relatively easy to fix and not as expensive as buying a new or used replacement motor.

- Joined

- Dec 25, 2011

- Messages

- 10,511

Take the belt off, turn it on, and give the pulley a spin in either direction. If it starts and runs quietly, and when you unplug it and it coasts to a stop you don't hear a Click, the centrifugal switch is probably stuck open. If you do hear a click, then probably either the starting capacitor is bad or the centrifugal switch contacts are burned or otherwise not making a connection.

So the fix is to lubricate and exercise the switch, replace the starting capacitor or burnish the switch contacts. Or maybe all three.

So the fix is to lubricate and exercise the switch, replace the starting capacitor or burnish the switch contacts. Or maybe all three.

- Joined

- Sep 23, 2015

- Messages

- 170

I will give it a try in the morning. I don't believe spinning the pulley got it to start though. I was in a hurry when I posted this morning, had to get to work, but will have more time tomorrow. Appreciate the replies. I'd love it to be a simple fix and not a motor replacement.

- Joined

- Apr 30, 2015

- Messages

- 11,288

Robert's advice above is correct. Either your starting capacitor is bad or you are having centrifugal start switch troubles; fixing either or both of those

is sure a lot cheaper than buying another motor.

A very few motors have an odd flat capacitor mounted in the base- if yours is like that, you'll have to substitute a cylindrical type and mount it outside the

motor somewhere and run wires in. They don't make 'em like that anymore

Mark

is sure a lot cheaper than buying another motor.

A very few motors have an odd flat capacitor mounted in the base- if yours is like that, you'll have to substitute a cylindrical type and mount it outside the

motor somewhere and run wires in. They don't make 'em like that anymore

Mark