- Joined

- Mar 25, 2013

- Messages

- 4,613

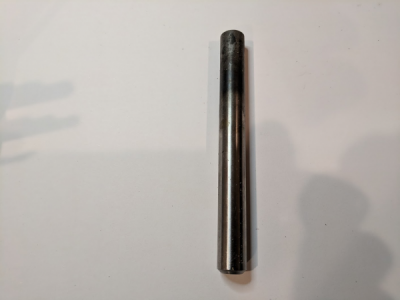

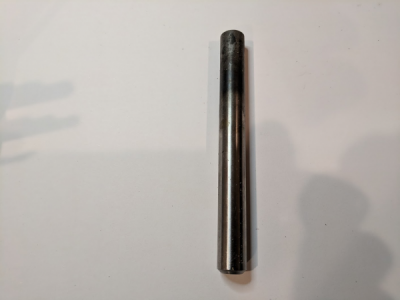

So I broke down and paid the money for an American made transfer punch set to replace my cheap Asian one with off center points. These are made by Spellman Manufacturing Company. This is what I got:

OK...as you can see, the business end has been heat treated. However, the tools were quenched in oil and then not cleaned of finished prior to packaging. There is black residue and scale on the end of all the tools! Is is just me, or is this unacceptable? The residue actually rubs of on your fingers when you handle it. These are supposed to be machined to .0025 undersize however I don't see how you could measure that since the scale coating is thicker than that? Yes I can clean these up and I am sure they will work just fine but really....

What are your thoughts on this?

Perplexed

Robert

OK...as you can see, the business end has been heat treated. However, the tools were quenched in oil and then not cleaned of finished prior to packaging. There is black residue and scale on the end of all the tools! Is is just me, or is this unacceptable? The residue actually rubs of on your fingers when you handle it. These are supposed to be machined to .0025 undersize however I don't see how you could measure that since the scale coating is thicker than that? Yes I can clean these up and I am sure they will work just fine but really....

What are your thoughts on this?

Perplexed

Robert