- Joined

- Dec 18, 2019

- Messages

- 6,426

Been reading about an ELS quite a bit. It seems the TI controller board is out of stock, and has been for at least six months. The Teensy 4.1 processor seems to have the guts and software support to be able to pull this off. So this is a thread where I start looking at this. Think I will look at Clough42's implementation and adopt some of it into my version of an ELS.

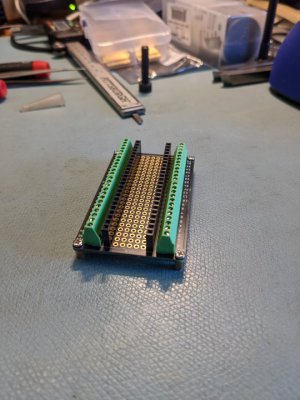

Towards that end, I have purchased a Teensy 4.1 and a little adapter board with screw terminals. In the beginning I expect to flounder about learning the platform, but that's kind of how it is starting on a new device. Think I will integrate a small 3 inch touch display to control this, rather than the traditional LED and push button board. I have used an ILI9341 before, so I will try it for the display. Making the display look ok is kind of a task in of itself, but it is doable. If someone knows of a repo where someone has done a Teensy ELS, with a display, let me know. No point of re-inventing the wheel. Haven't started the repo search in earnest, but a preliminary look doesn't show anything obvious.

How easy this will be without ICE (in circuit emulation) is an open question. But, hey, I'm a glutton for punishment. This is obviously not going to be a quick project, as I will have to do a lot of learning along the way. Based on a complex arduino project (a doppler radar chronometer) I finished a couple of years ago, I expect something working in maybe 3-4 months, but not really working well until maybe 6-8 months. At least this time I will be able to reuse some of my display code. Maybe I will get it working by the time the TI boards are available again - or not. Won't know until I try.

Towards that end, I have purchased a Teensy 4.1 and a little adapter board with screw terminals. In the beginning I expect to flounder about learning the platform, but that's kind of how it is starting on a new device. Think I will integrate a small 3 inch touch display to control this, rather than the traditional LED and push button board. I have used an ILI9341 before, so I will try it for the display. Making the display look ok is kind of a task in of itself, but it is doable. If someone knows of a repo where someone has done a Teensy ELS, with a display, let me know. No point of re-inventing the wheel. Haven't started the repo search in earnest, but a preliminary look doesn't show anything obvious.

How easy this will be without ICE (in circuit emulation) is an open question. But, hey, I'm a glutton for punishment. This is obviously not going to be a quick project, as I will have to do a lot of learning along the way. Based on a complex arduino project (a doppler radar chronometer) I finished a couple of years ago, I expect something working in maybe 3-4 months, but not really working well until maybe 6-8 months. At least this time I will be able to reuse some of my display code. Maybe I will get it working by the time the TI boards are available again - or not. Won't know until I try.