-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Annealing machine?

- Thread starter TrxR

- Start date

- Joined

- May 17, 2011

- Messages

- 11

Don't know how elaborate you want to get but there are some videos on you tube....this one is as simple as it gets, you would need to do a little experimenting with the brass time in the flame.. I have done it like this and it works fine...

http://www.youtube.com/watch?v=AOqlE53bOfo

http://www.youtube.com/watch?v=AOqlE53bOfo

My version I plan on building will have two torches for more even heat.

By the way that one is not mine but I plan on making one similar. I just got to figure out how I am going to get a gear like that.

Thanks

Am looking at using a rear motorcycle sprocket for my project annealer but you probably have had your machine up and running for a while now. May we have an update of what you settled for?

- Joined

- Oct 21, 2013

- Messages

- 33

I also want an annealing machine. Ken Light builds one that sets the standard for the design discussed so far...but I think I'll go with this type:

Something I really like about this type is that the case rotates several times while in the flame, so there is no question that it got enough heat or that it was heated evenly.

Something I really like about this type is that the case rotates several times while in the flame, so there is no question that it got enough heat or that it was heated evenly.

- Joined

- Dec 30, 2015

- Messages

- 41

A lot of work for a simple job. Line cases up on a piece of bar stock over a pan of water. Apply torch in a circular motion around each case while you count to four. Knock case in water and move to next. Dry the cases and move on. No fancy single use wheel to store.

Jeff

Jeff

- Joined

- Oct 21, 2013

- Messages

- 33

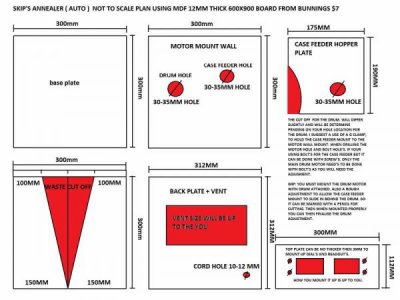

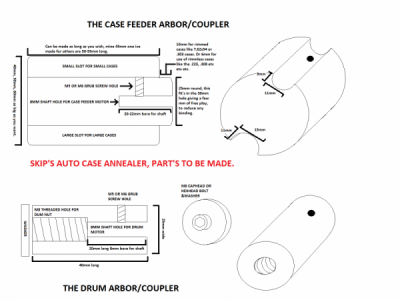

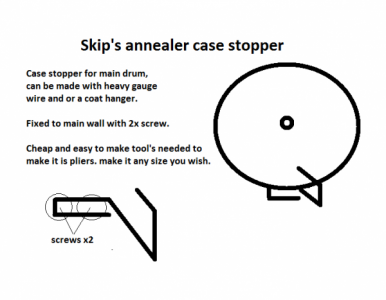

I have built Skip's version of the case annealer and it is simple and works well. It originated from one of the members of shootingaustralia.net forum here in Australia, you have to sign up and become a member to view the post. Attached a few photos of the build instructions.

View attachment 127519 View attachment 127520 View attachment 127521 View attachment 127522

Does he offer plans? I thought he only sold complete units? Plans would be great; save a few bucks and no chance on any parts being incorrect voltage. BTW-check his thread. I signed up to ask if he would build one to work on US 110 volt power, before I saw your reply here.

- Joined

- Oct 21, 2013

- Messages

- 33

A lot of work for a simple job. Line cases up on a piece of bar stock over a pan of water. Apply torch in a circular motion around each case while you count to four. Knock case in water and move to next. Dry the cases and move on. No fancy single use wheel to store.

Jeff

I want the process to be as consistent as possible. I like wildcats, high-quality brass from Europe, and long-range barrel burners. Longer brass life = less money spent on brass and less fireforming.

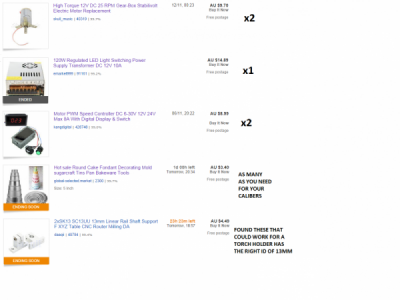

Lee, the attached photos are the plans to build from. Skip has no real specific step by step plans, but from the blue print and seeing the video it is easy to build. The motors are all 12 volts and all you need is the correct 110v step down transformer to suit you market. All parts are available from ebay. If you PM me your email I can send you the attached blueprints in pdf form. I think the whole thing cost me about $50.00 to build not including the gas torch.