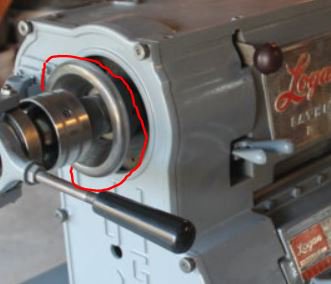

Hey there, I'm in the midst of rebuilding the head on my craigslist 2557-V, and I have a problem. I am trying to figure out if the part on the back of the spindle that holds on the spindle lock (the part that locks the cone pulley in place for hi/low range) in place is threaded or simply pressed on. Either way, it's pretty well stuck on there. This is kinda the big issue I'm having.

I'm kinda bummed my lathe isn't as pretty as yours, but mine came with all of the accessories (turret, tailstock, two chucks, and a boatload of collets so I think I came out about even)

Either way, thanks for the help in advance. I might ask for contact info for your rebuilder.

I'm kinda bummed my lathe isn't as pretty as yours, but mine came with all of the accessories (turret, tailstock, two chucks, and a boatload of collets so I think I came out about even)

Either way, thanks for the help in advance. I might ask for contact info for your rebuilder.