I got the machine home. The move was a rather simple one. I rented a Ryder truck with a lift gate. I brought my buddy ,that's a rigger, just in case. I brought my engine hoist a good solid pallet, a pallet jack and plenty of straps. The guy at the school loaded it onto the pallet with a fork lift. We then strapped it to the pallet. Then he loaded it onto the truck for me with the fork lift.

) That was easy! The auction site said that we had to rig it and move it ourselves.:whistle: I could have saved $125 on the truck rental, but in hindsite the truck and lift gate made it so easy..... i've had a tougher time moving stoves and air conditioners. I didn't take any pictures of the move because it was 123 and out the door we went.

I gave the machine a good look over at the place. The good news is that it is a hydraulic machine. The bad news is that the hydraulic power pack isn't there, as I suspected. I made a stink about it as it wasn't listed as missing on the site. But in all fairness, I had bought it fully thinking that it was a manual machine. The maintenance guy at the school felt bad about it, I think that's why he helped me load the machine. This thing is in really good shape. It looks as good as the auction pictures, if not better. Never been repainted, it's clean, but needs to be cleaned better. This machine hasn't seen much use at all. All the other hydraulic components are there. They also removed the broken lubricator. So now I'm on the hunt for a hydraulic power pack for this thing and a lubricator.

It also has the accu-rite absolute zero II scales for the x and z axis with all the cables. It sais they're accurate to .0001". I gotta find a DRO display for that too.

If anybody knows where I could start looking for these items, please let me know.

I'll get some better pictures of it once I have it in place but here are the shots I could get right now.

The hydraulic controls

Inside the control box and the DRO wires

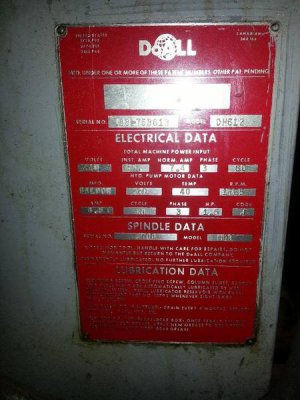

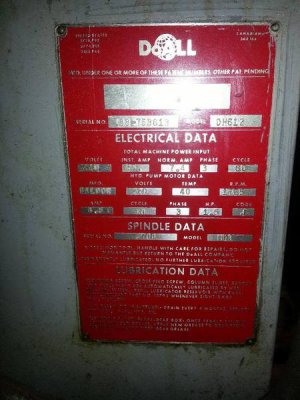

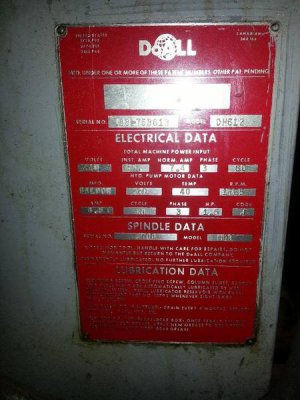

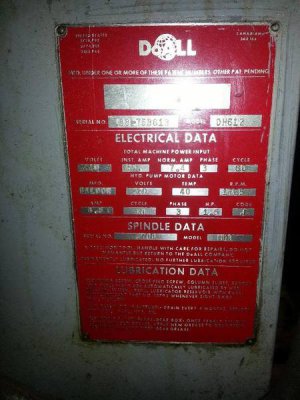

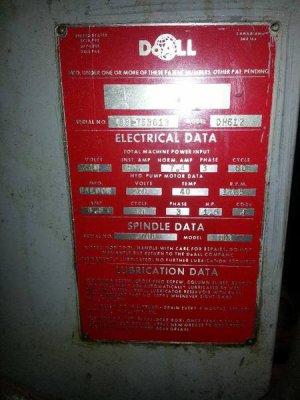

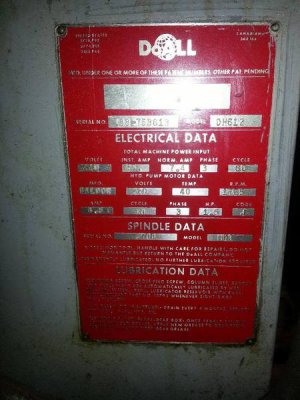

Some pictures of the tags.

The accuRite scales.

That's all I got for now.

Marcel