- Joined

- Nov 1, 2018

- Messages

- 98

I needed a small belt grinder. So, I decided to build the one using my cheap bench grinder as a donor. I removed a rough grinding wheel on the right side. That’s a great place for the belt.

The motor isn’t really powerful – just about 250W. It runs at 3600RPMs. If I use 3-inch wheels to drive the belt, the linear grinding speed would be about 14m/sec, or 43feet/sec. I learnt that sanding wood typically requires 10-15m/sec speed, and grinding metals typically requires 15-30m/s. So, having 14m/sec on a 3-inch wheels seemed like a good trade-off for both wood and metal.

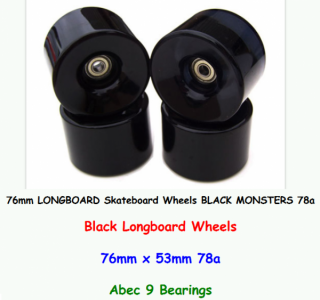

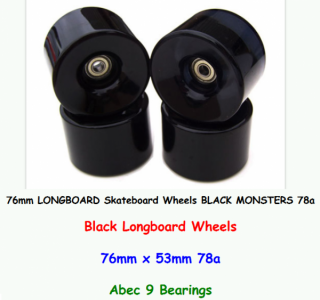

I found nice 3-inch longboard wheels I can use to rub the belt. The wheels are 2” wide, and 4” wide roller can be made from 2 wheels. This gives me the width of the grinding belt – 4-inch. What’s also interesting, when two wheels are tightened together, they form a barrel-shape roller because they have internal chamfers, and the edges of the wheels deform more than the body.

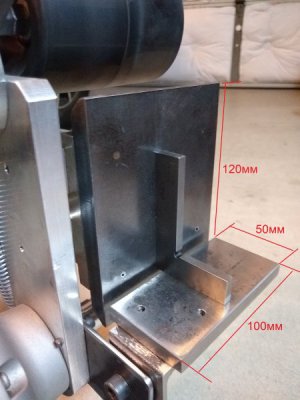

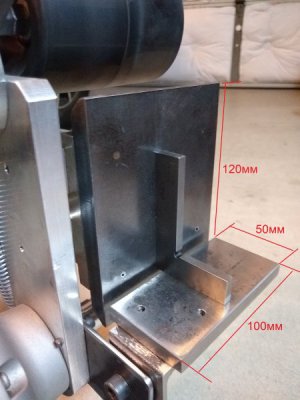

I picked-up 4” x 24” belt just because I needed a small grinder. Vertical and horizontal tables are made of ½” steel. The mounting plate is made of ½” aluminum.

It looks like the belt isn’t running fast on a video. That’s because of video frame rate, it runs fast actually. The sides of the cube are flat, and the edges are sharp as a knife! I’m happy about the grinder!

The motor isn’t really powerful – just about 250W. It runs at 3600RPMs. If I use 3-inch wheels to drive the belt, the linear grinding speed would be about 14m/sec, or 43feet/sec. I learnt that sanding wood typically requires 10-15m/sec speed, and grinding metals typically requires 15-30m/s. So, having 14m/sec on a 3-inch wheels seemed like a good trade-off for both wood and metal.

I found nice 3-inch longboard wheels I can use to rub the belt. The wheels are 2” wide, and 4” wide roller can be made from 2 wheels. This gives me the width of the grinding belt – 4-inch. What’s also interesting, when two wheels are tightened together, they form a barrel-shape roller because they have internal chamfers, and the edges of the wheels deform more than the body.

I picked-up 4” x 24” belt just because I needed a small grinder. Vertical and horizontal tables are made of ½” steel. The mounting plate is made of ½” aluminum.

It looks like the belt isn’t running fast on a video. That’s because of video frame rate, it runs fast actually. The sides of the cube are flat, and the edges are sharp as a knife! I’m happy about the grinder!