- Joined

- Nov 28, 2016

- Messages

- 2,332

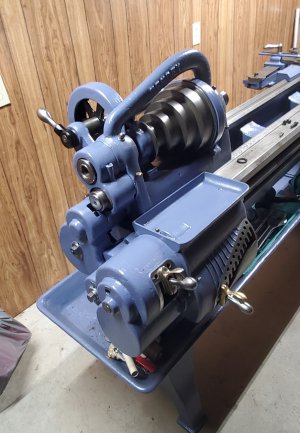

I've finally found some time to work on the Hendey again... I've finished assembling the gear train between the headstock and the QCGB. I've also finished cleaning and prepping all of the gear covers and guards for paint. The smaller gearbox is still soaking in the degreaser, hopefully I'll be able to get it cleaned and painted this week.

In one of my last updates I mentioned that the longitudinal feed pinion was rubbing the rack under the bed... what was happening was, when moving the carriage toward the chuck, there was a place about 6 inches from the chuck where it would suddenly get very tight. After checking everything thoroughly, I found one bent tooth on the rack gear...

I removed the rack, (which meant disassembling the QCGB again and removing the lead screw so I could get to the rack bolts) and put it on the workbench... I basically 'cold worked' the bent tooth back into useable condition. After reinstalling the rack, the carriage now moves smoothy through it's full travel. Now I have to reassemble the QCGB and the other gearing.

-Bear

In one of my last updates I mentioned that the longitudinal feed pinion was rubbing the rack under the bed... what was happening was, when moving the carriage toward the chuck, there was a place about 6 inches from the chuck where it would suddenly get very tight. After checking everything thoroughly, I found one bent tooth on the rack gear...

I removed the rack, (which meant disassembling the QCGB again and removing the lead screw so I could get to the rack bolts) and put it on the workbench... I basically 'cold worked' the bent tooth back into useable condition. After reinstalling the rack, the carriage now moves smoothy through it's full travel. Now I have to reassemble the QCGB and the other gearing.

-Bear