- Joined

- Nov 23, 2020

- Messages

- 787

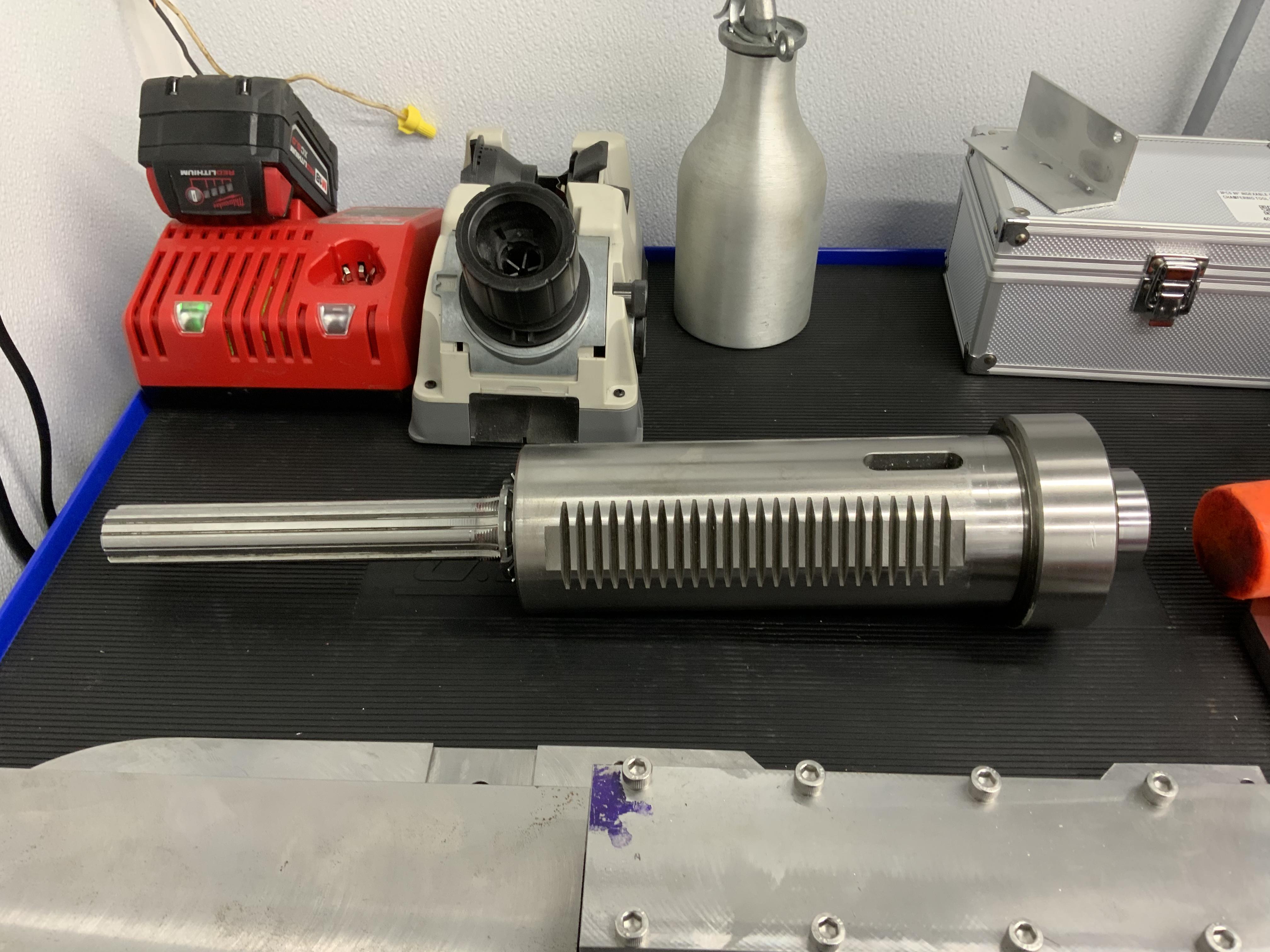

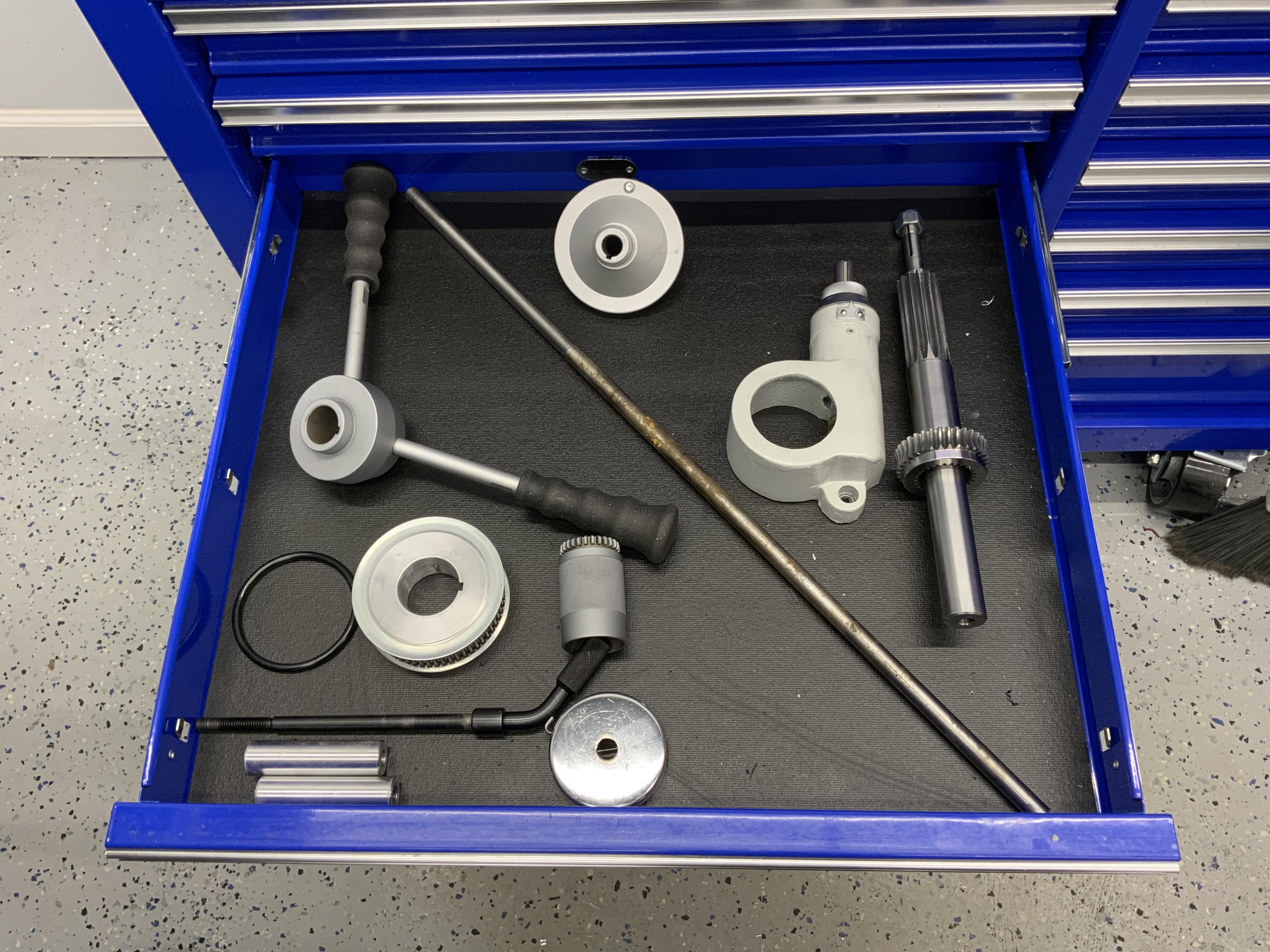

Did a little work on the scale. Now I need to fab a holder for the read head. I cut the opening for the factory quill stop taller, so I can get full range of quill motion for the read head and scale. Doing the final adjustments should not be tough, as I can dial everything with machining stand offs the exact thickness of the cover, and mount the scale on the standoffs without the cover to access the adjustments behind. I am thinking this will wait till I remove the spindle housing to install the new clamp on plate to hold the read head assembly (old quill stop) and a portion that stands off in front to hold the 1/2"20 rod for the educated nut. My spindle tach was actually working half the time today. Every time I start the machine, it is a 30/70 chance it will work. PM is aware and looking into a replacement board, but we are not sure which board it is. I replaced the wire with another ethernet cable, but nope. Not the cable.