- Joined

- Feb 8, 2014

- Messages

- 11,144

I can't say that I have ever seen Power Factor correction capacitors used in a phase converter. That's a new one. Your values for your run caps are not shown. All I can say is watch overdoing it with the run capacitors on the RPC. Too much capacitance and you will get a wild leg in the 300 to 500 volt range with no load.

I have tuned most every one I have touched down to within 5% A to C and B to C voltage wise and they are typically very stable under load.

Now as far as the motor. Is it compressor rated or not?

If compressor rated, what type of compressor?

It's important to understand that rating. If it's rated for a screw compressor then your fine. It's 100% duty cycle.

COmpressor motors are typically NOT rated to be run for hours on end. Think about how your compressor works. You use air, it comes on and pressure builds up and it shuts off. It's off for a while then cycles again.

RPC's run and run as long are you are using them. You also give up some efficency for starting torque with a compressor motor. Meaning it will draw a bit more power, and generate a bit more heat than a pump or fan motor.

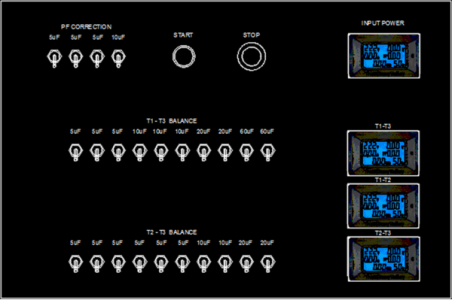

I'll be very carefully monitoring the voltage and Power Factor with built in instrumentation. Measuring leg to leg output parameters as will as input voltage, current, and power factor. The input and output will will be measured with separate devices attached across their respective legs. Like I said above, I tend to over engineer stuff.

The capacitors are roughly calculated by this formula:

CL1-L3 = 4 to 5 times the motor horsepower = 75 (20+20+10+10+10+5+5+5+5)

CL2-L3 = 10 to 15 times the motor horsepower = 180 (60+60+20+20+10+10+5+5+5+5)

PF COR = (10+5+5+5+5)

Where the capacitors will be switched in and out manually by toggle switches for now. Once I get the system running, they may be adjusted on the fly by a PLC if needed.

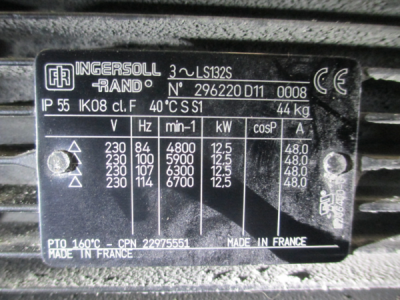

The compressor motor is a rotary screw driver, rated for continuous inverter duty, 12.5KW, 3600 RPM nominal. Also interestingly enough rated for 6700 RPM at 114 Hz. Would make a heck of a spindle motor If you had something big enough to run it on.

)

)

These will be checked against my Fluke meters. If I can get comparative values between the panel meters I'll be happy.

These will be checked against my Fluke meters. If I can get comparative values between the panel meters I'll be happy.