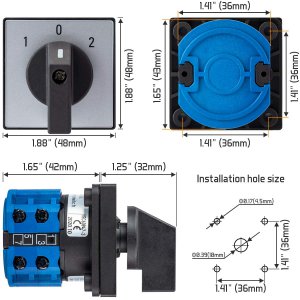

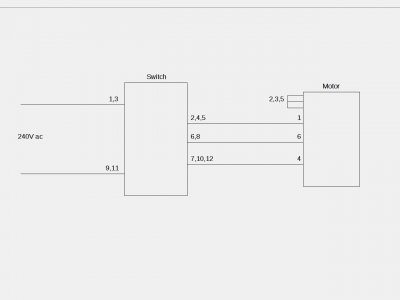

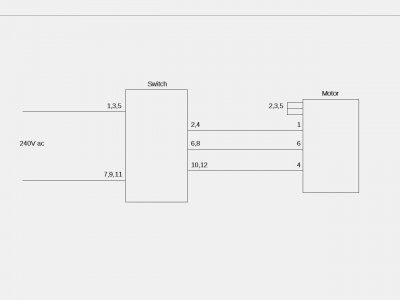

I was recently given a Jet 1024 that is in rather poor shape, but I am working to get it operational order. I have verified that the single phase 120v induction motor will run in both rotations according to the wiring diagram on the motor tag. When I got it, it was wired to a cam/toggle switch on the face in the CCW direction only. I have no idea if the switch on the machine was original, but I suspect that it was not. I want to re-wire it to use a cam or toggle type switch in the factory location similar to the switch in the attached photos. Can someone help me with a switch recommendation that I might get through Amazon to accomplish forward and reverse motor rotation through a single switch? I'll also need assistance to get the recommended switch wired to my machine. Thank you for your help!