B

Bill Gruby

Forum Guest

Register Today

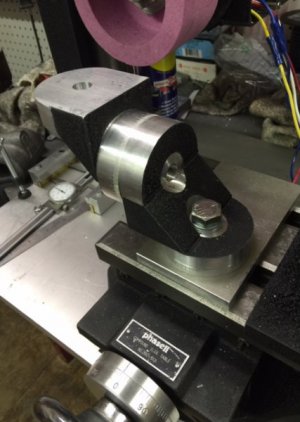

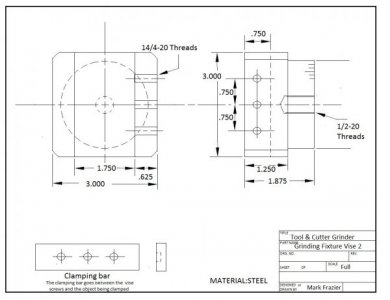

At the front of the base of the fixture, because it is aluminum, a small extension of the base out and under the dial would dampen any vibration just a bit more. Maybe not? Just an idea.

"Billy G"

"Billy G"