-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Another Tool & Cutter Grinder

- Thread starter Mark_f

- Start date

While I am waiting on some metal for the fingers on my bending brake, I thought I would get back to this project.

I spent a lot of time deciding what I wanted in this grinder and while the table provides the X and Y movement, it would be so easy to make a tilting head similar to the Cutter master machine and be able to grind end mills and drills, BUT, I wanted more capabilities without getting complicated. I love the Bonelle grinder I made but it is too complex and time consuming to set up every time you want to do something. I want it to be easier and simple. So......... I studied several brands and looked at the features and came up with a design that will fit all my parameters. I also want this machine to be very heavy and stable. I think I have it now. this machine will take two men to pick up and move. It will be heavy , which translates to sturdy. It will not be a whole lot bigger than the Bonelle, but will be higher and deeper. I spent a lot of hours designing the grinding head and column. I have it detailed enough to start construction.

, which translates to sturdy. It will not be a whole lot bigger than the Bonelle, but will be higher and deeper. I spent a lot of hours designing the grinding head and column. I have it detailed enough to start construction.

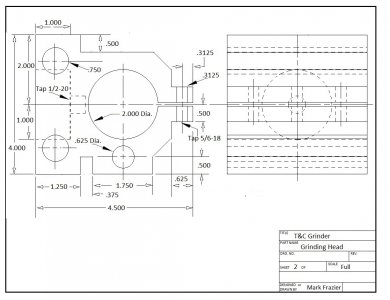

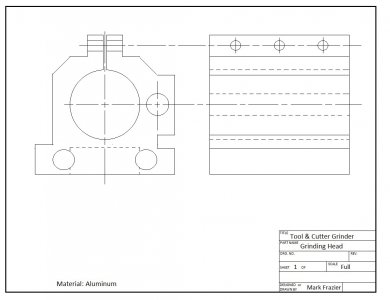

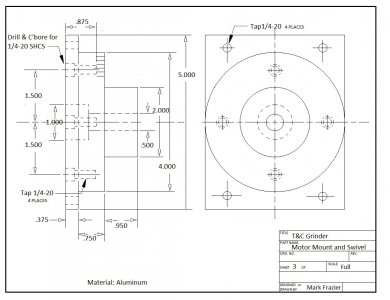

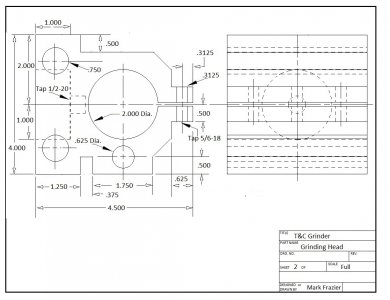

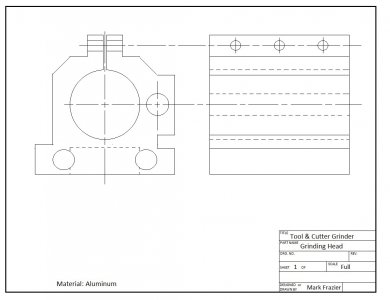

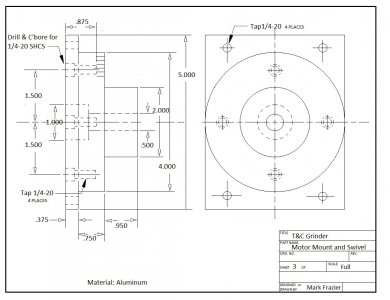

This is the drawings for the grinding head. it is made from a 4" X 4" X 4 1/2" block of 6061 aluminum. I am using this because I happen to have it. Cast iron would be better, but......

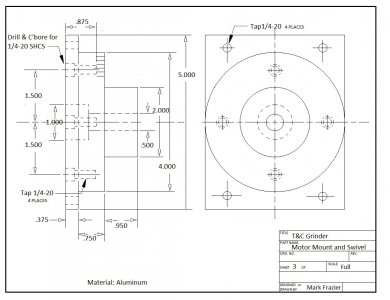

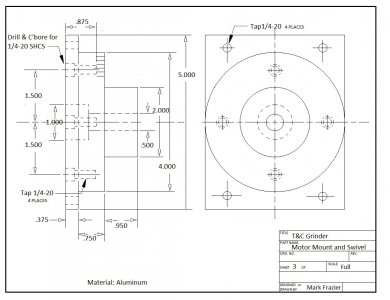

The column will be 2" diameter cold roll bar. Again because I have it. I was thinking bigger but that would increase the head size also , so a compromise. There will be double split cotters to lock the swivel head in position. The motor will mount directly on the grinding head and the wheel will mount directly on the motor shaft. ( Now before a bunch of you flood me with the thought about vibration in the cutter wheel mounting it directly on the motor, I have researched this and even tested the idea. As long as you have good quality ball bearings in the motor, it is not a problem and the 60 cycle frequency has no effect that can be detected). The motor will swivel 360 degrees as will the column also, making any angular position possible with just two settings. The column and swivel head will be marked in 1 degree increments but with the spacing on the marks you should be able to set a 1/4 degree with great accuracy. The column will rise and lower just like I did it on the Bonelle. There will be a precision acme screw, 1/2"-10, giving .100" travel per turn and I have an anti back lash nut for the screw, eliminating any back lash in the assembly.

The degree markings for the motor swivel and the column swivel will be engraved on a 4" diameter wheel. this should make the one degree marks approximately .127" apart. That is why it will be easily set accurately.

There are three bolt clamps in the rear of the head to secure the head to the column. The top and bottom bolts will be lock bolts ( have a nylon insert in the threads to hold their setting). These will be set to put a light drag on the head sliding on the column. the center bolt will have a 1/4 turn locking handle to secure the grinding head at any setting vertically.

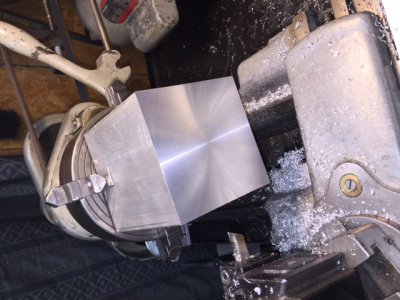

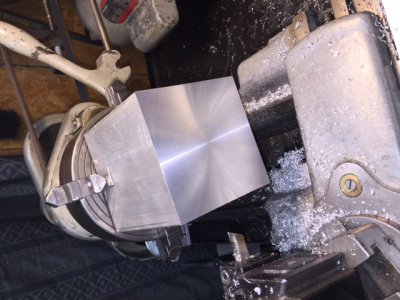

I put the aluminum block in my 4 jaw chuck to face the front. this will be the reference surface everything is measured from. All the machining for this view on the print will be completed before it is taken out of the chuck.

I put the aluminum block in my 4 jaw chuck to face the front. this will be the reference surface everything is measured from. All the machining for this view on the print will be completed before it is taken out of the chuck.

The face is flat and smooth. Ready for finish machining. I will get more done this week end.

The face is flat and smooth. Ready for finish machining. I will get more done this week end.

I spent a lot of time deciding what I wanted in this grinder and while the table provides the X and Y movement, it would be so easy to make a tilting head similar to the Cutter master machine and be able to grind end mills and drills, BUT, I wanted more capabilities without getting complicated. I love the Bonelle grinder I made but it is too complex and time consuming to set up every time you want to do something. I want it to be easier and simple. So......... I studied several brands and looked at the features and came up with a design that will fit all my parameters. I also want this machine to be very heavy and stable. I think I have it now. this machine will take two men to pick up and move. It will be heavy

, which translates to sturdy. It will not be a whole lot bigger than the Bonelle, but will be higher and deeper. I spent a lot of hours designing the grinding head and column. I have it detailed enough to start construction.

, which translates to sturdy. It will not be a whole lot bigger than the Bonelle, but will be higher and deeper. I spent a lot of hours designing the grinding head and column. I have it detailed enough to start construction.This is the drawings for the grinding head. it is made from a 4" X 4" X 4 1/2" block of 6061 aluminum. I am using this because I happen to have it. Cast iron would be better, but......

The column will be 2" diameter cold roll bar. Again because I have it. I was thinking bigger but that would increase the head size also , so a compromise. There will be double split cotters to lock the swivel head in position. The motor will mount directly on the grinding head and the wheel will mount directly on the motor shaft. ( Now before a bunch of you flood me with the thought about vibration in the cutter wheel mounting it directly on the motor, I have researched this and even tested the idea. As long as you have good quality ball bearings in the motor, it is not a problem and the 60 cycle frequency has no effect that can be detected). The motor will swivel 360 degrees as will the column also, making any angular position possible with just two settings. The column and swivel head will be marked in 1 degree increments but with the spacing on the marks you should be able to set a 1/4 degree with great accuracy. The column will rise and lower just like I did it on the Bonelle. There will be a precision acme screw, 1/2"-10, giving .100" travel per turn and I have an anti back lash nut for the screw, eliminating any back lash in the assembly.

The degree markings for the motor swivel and the column swivel will be engraved on a 4" diameter wheel. this should make the one degree marks approximately .127" apart. That is why it will be easily set accurately.

There are three bolt clamps in the rear of the head to secure the head to the column. The top and bottom bolts will be lock bolts ( have a nylon insert in the threads to hold their setting). These will be set to put a light drag on the head sliding on the column. the center bolt will have a 1/4 turn locking handle to secure the grinding head at any setting vertically.

I put the aluminum block in my 4 jaw chuck to face the front. this will be the reference surface everything is measured from. All the machining for this view on the print will be completed before it is taken out of the chuck.

I put the aluminum block in my 4 jaw chuck to face the front. this will be the reference surface everything is measured from. All the machining for this view on the print will be completed before it is taken out of the chuck. The face is flat and smooth. Ready for finish machining. I will get more done this week end.

The face is flat and smooth. Ready for finish machining. I will get more done this week end.

Last edited by a moderator:

There is an error in the motor swivel plate. It will not be aluminum but instead made from cold finish steel. the reasons are I want dissimilar metals where the actual swivel is and the steel is heavier and sturdier.

I have been told I was a little nuts for doing another grinder, but this one is soooooo much better, I just can't help myself.

for doing another grinder, but this one is soooooo much better, I just can't help myself.

I have been told I was a little nuts

B

Bill Gruby

Forum Guest

Register Today

One more time I will ask you new people to pay close attention to Marks' machinery. That lathe is not a big 12 inch beast. Mark is highly skilled at coaxing the max from his equipment. He also does not ask them to do something they are not capable of doing. Mark is the Master of his shop, not the machines. Keep up the great work Mark, you are amazing.

"Billy G"

"Billy G"

- Joined

- Feb 2, 2013

- Messages

- 3,613

i like your thinking and your beautiful work, Mark

The hand wheels for the table on this grinder came today. They are 4 inches in diameter.

I got these off eBay at a good price. I will drill and tap a hole for the spinner handles ( I will make) and ream the center hole for the table shafts. They are nice cast iron chrome plated wheels. I think I should get a couple more of these.

I got these off eBay at a good price. I will drill and tap a hole for the spinner handles ( I will make) and ream the center hole for the table shafts. They are nice cast iron chrome plated wheels. I think I should get a couple more of these.

I got these off eBay at a good price. I will drill and tap a hole for the spinner handles ( I will make) and ream the center hole for the table shafts. They are nice cast iron chrome plated wheels. I think I should get a couple more of these.

I got these off eBay at a good price. I will drill and tap a hole for the spinner handles ( I will make) and ream the center hole for the table shafts. They are nice cast iron chrome plated wheels. I think I should get a couple more of these.- Joined

- Mar 19, 2014

- Messages

- 2,680

Might want to check out the handwheels at Enco. Especially when they have their discount and free shipping. Like, right now! I have gotten some of there in the ruff cast iron handwheels. They machined beautifully, no complaints.The hand wheels for the table on this grinder came today. They are 4 inches in diameter.

View attachment 123841 I got these off eBay at a good price. I will drill and tap a hole for the spinner handles ( I will make) and ream the center hole for the table shafts. They are nice cast iron chrome plated wheels. I think I should get a couple more of these.

- Joined

- Dec 11, 2014

- Messages

- 891

The hand wheels for the table on this grinder came today. They are 4 inches in diameter.

View attachment 123841 I got these off eBay at a good price. I will drill and tap a hole for the spinner handles ( I will make) and ream the center hole for the table shafts. They are nice cast iron chrome plated wheels. I think I should get a couple more of these.

Where did you find them Mark?

Those look really nice. Are they good and solid?

I need to get a couple of them for another project also.