- Joined

- Jan 2, 2019

- Messages

- 6,488

I have the same machine, all be it without the modification. When I bought it for $300 back around 2005 I probably wouldn't have noticed it and surely wouldn't have passed it up because of such a mod.The modification may be unsightly to some but has no effect on the functionality of the machine. As mentioned, it was probably done when the operator needed to turn a part slightly larger than the lathe was designed to handle. While this modification is a bit crude but can be dressed to look as though it was an integral part of the machine when it was built.

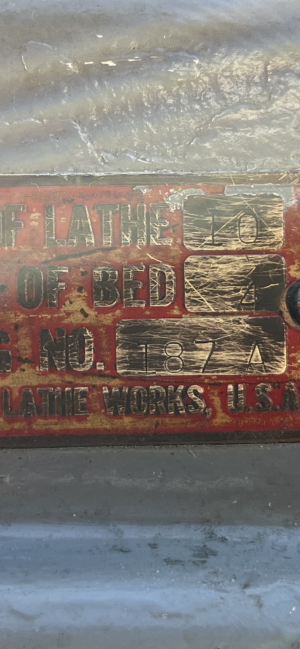

Over the years I've seen a number of smaller machines with the same modification. My Seneca Falls lathe has a similar although much smaller modification. Originally my machine was sold as a 9" even though in reality it had a throw of 10 1/4". Sometime in its professional life the modification was made to allow the chuck jaws to swing at 11". I say in its professional life because I know the history of the machine. It was run for nearly 40 years in a prototype shop by my wife's grandfather. When he retired, it was given to him as a retirement present. When he passed it went to my wife's father. When he passed, I became the custodian. It's been nearly 60 years since the modification was made, and in all that time it's never interfered with fabricating a single part.

If you're primarily interested in the cosmetics of a machine this may not be the one for you. If you're primarily interested in functionality, it's still worth looking at. As an FYI none of the machines in my shop are beauty queens. They all came from industrial and commercial shops and show some signs of the years of service they've put in. I look at them as battle scared veterans. Maybe not the beauty queens they once were, but still perfectly capable of turning out quality parts.

Here's a picture of the modification on my Seneca Falls machine.

I'm definitely not one to obsess over cosmetics on machine tools, they were made to work and if accurate enough for the job at hand that's what really matters.

The bigger challenge with vintage machinery IMHO is the limited speed range and lack of a QCGB. You can still make good parts, and adding a 3ph motor w/VFD to both my lathes is definitely a worthwhile addition. One of the best things though about my Star that I didn't even realize when I got it is the factory taper attachment. Nope, won't be getting rid of it anytime soon regardless. It's a joy to own and operate.

However, if I was looking for my first lathe and had a reasonable budget I'd be setting my sites higher than the one the OP posted. Here's a Logan for $1100 in Oxnard which would probably fit the bill and require much less effort to make good parts with, bonus that Scott Logan still provides parts and support for the brand.

Lathe 955 Logan - tools - by owner - sale

Metal working lathe with 3 & 4 jaw chucks. Tool holder and cutting tools. Eight 0 five nine one zero 9 3 seven four. Text anytime if interested.

ventura.craigslist.org

Good luck with whatever you do and keep asking questions here.

Cheers,

John