- Joined

- Jun 12, 2018

- Messages

- 712

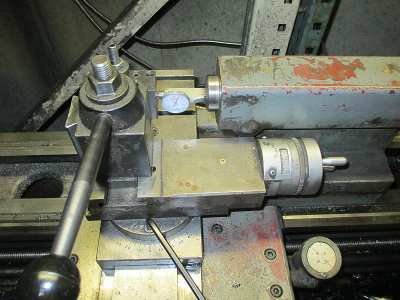

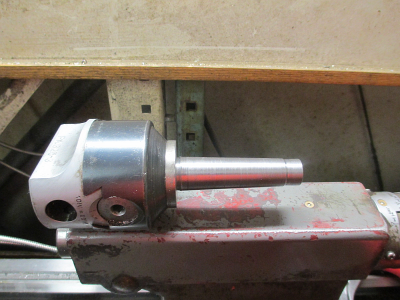

I'm trying to hold an MT3 dead center on my lathe. I used my 3 jaw chuck at first, then moved on to a 4 jaw independent chuck. There's a small part on the end of that dead center that's not tapered and that's where I'm holding it. I put 2 indicators on it, one of the left side and one on the right. I'm having a heck of a time trying to center it in. I can get centered at right end, but the left side is visibly wobbly, clearly not centered.

What am I doing wrong? Any tips? Do I even need 2 dial indicators to center this in? Using a live center, pushing on it from the tailstock side didn't help.

What am I doing wrong? Any tips? Do I even need 2 dial indicators to center this in? Using a live center, pushing on it from the tailstock side didn't help.