- Joined

- Aug 23, 2013

- Messages

- 970

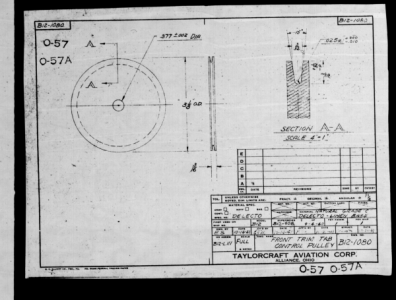

I am going to make some phenolic pulleys, I have a local tool grinder make me a tool to turn the groove, I am going to use a HSS parting tool, what angles should be on the tool for rake, etc. ? I also need to bore a precise hole and broach a square hole, Can I use a chucking reamer and a standard broach? I dont think that drill bit will be precise enough. I have about a +- .002 tolerance on the hole. I will post pics when I get a chance. Tim