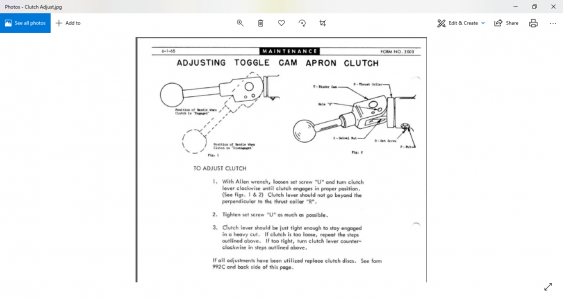

WELL HERE GOES WITH ANOTHER QUESTION REGARDING MY SBL HEAVY 10. IN MOST ALL PICTURES AND HOW TO USE BOOKS ETC, THE CLUTH IS SHOWN TO BE OPERATED BY MEANS OF A KNOB! MY LATHE HAS A LEVER WITH WHAT APPEARS TO BE A TENSIONING KNURLED RING WHICH I ASSUME WOULD ALLOW TIGHTENING OF THE LEVER WHICH WOULD TIGHTEN THE CLUTCH. MINE DOESN'T SEEM TO MAKE ANY DIFFERENCE. BEFORE I GO TEARING THE APRON APART, DOES ANYONE HAVE ANY IDEAS OR EXPERIENCE WITH THE LEVER OPERATED CLUTCH???

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Apron Clutch Knob Vs Lever

- Thread starter 1mondo

- Start date

- Joined

- Oct 3, 2015

- Messages

- 982

- Joined

- Mar 10, 2012

- Messages

- 1,368

I thought of converting mine star knob to the lever but most of the guys I read about that did that went back to the star. You can kinda slide into activating the clutch more smoothly than with the lever....so they say.

- Joined

- Jun 13, 2019

- Messages

- 38

See if this helps.

Darn it. I can’t download