- Joined

- Mar 26, 2018

- Messages

- 8,406

A co-worker asked me to help him build/change his AR upper barrel and hardware. Sure, no sweat.

As I recall, the A2 front sights and integral gas block are held with two tapered pins.

This particular upper was PSA built. It seemed pretty clear which side was the drive side. No luck.

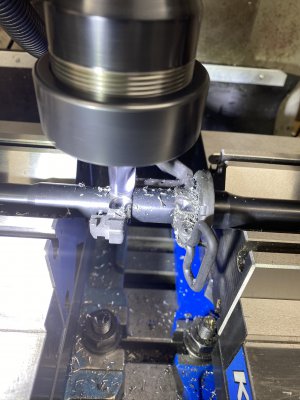

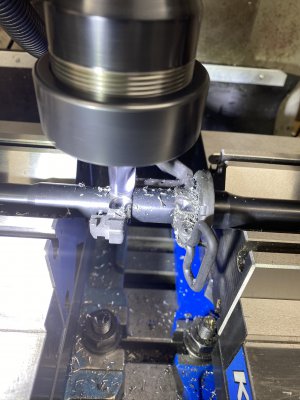

He wasn’t going to reuse the sight so I mounted it in my mill and used an end mill to relieve the stress in an effort to remove this part.

Come to find out, they are straight pins. Am I losing my mind? I have built several of these over the years and I could have sworn they were tapered.

It all went swimmingly once I cut the darn things out.

As I recall, the A2 front sights and integral gas block are held with two tapered pins.

This particular upper was PSA built. It seemed pretty clear which side was the drive side. No luck.

He wasn’t going to reuse the sight so I mounted it in my mill and used an end mill to relieve the stress in an effort to remove this part.

Come to find out, they are straight pins. Am I losing my mind? I have built several of these over the years and I could have sworn they were tapered.

It all went swimmingly once I cut the darn things out.