-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Articulated Arm Holder

- Thread starter rwm

- Start date

- Joined

- Mar 25, 2013

- Messages

- 4,614

Thanks! I'm glad someone is watching. That knurled piece was just a piece of scrap to test the concept. Although you raise an interesting point. Perhaps knurling could be involved....Hi Robert,

Cool build, looking forward to seeing more. Beautiful finish too. Will you be knurling the center portions of the shafts/rods (un-machined area)?

R

- Joined

- Mar 25, 2013

- Messages

- 4,614

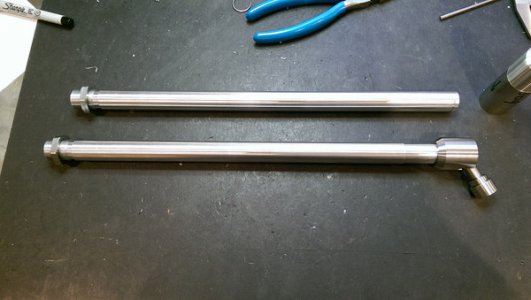

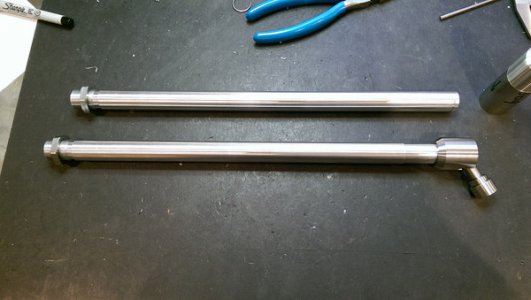

Finished the distal arm:

I went with 14" arms since no one objected!

Ground the wedges and indexed the two halves of the elbow:

Looking good! Still need to machine the socket for the proximal arm.

Should the actuator arms be steel? Can I get away with aluminum for weight savings? I saw some relatively cheap Ti on eBay?

R

I went with 14" arms since no one objected!

Ground the wedges and indexed the two halves of the elbow:

Looking good! Still need to machine the socket for the proximal arm.

Should the actuator arms be steel? Can I get away with aluminum for weight savings? I saw some relatively cheap Ti on eBay?

R

T

TOOLMASTER

Forum Guest

Register Today

to nice for welding now...

- Joined

- Mar 25, 2013

- Messages

- 4,614

So here's where I am. A few technical problems. Funny, I thought locking the ball joints might be an issue. Turns out unlocking the wedges in the elbow are the issue! Hard to predict.

I think material science may play a role here. I am using bearing bronze for the pushrod wedges. The round wedges are 304. The housing is aluminum.

When you crank down on the joint it locks the ball joints nicely but does not release as smooth as I would like since the wedges stay locked. I have re-ground the wedges to about 30 deg and this seems to have helped. I am considering polishing all the surfaces. Should I change material? Should I have SS on SS polished? Bronze on bronze? I am also considering using a 1/2" ball bearing as a pushrod actuator. That may be able to roll and unlock easier? Thoughts invited.

I am very close to a perfect solution!

R

I think material science may play a role here. I am using bearing bronze for the pushrod wedges. The round wedges are 304. The housing is aluminum.

When you crank down on the joint it locks the ball joints nicely but does not release as smooth as I would like since the wedges stay locked. I have re-ground the wedges to about 30 deg and this seems to have helped. I am considering polishing all the surfaces. Should I change material? Should I have SS on SS polished? Bronze on bronze? I am also considering using a 1/2" ball bearing as a pushrod actuator. That may be able to roll and unlock easier? Thoughts invited.

I am very close to a perfect solution!

R

Last edited: