- Joined

- Jan 1, 2021

- Messages

- 10

I have one of these machines it looks like the same machine as a Jet 12x36 same green, even has the same metal tag on the front just says Astro

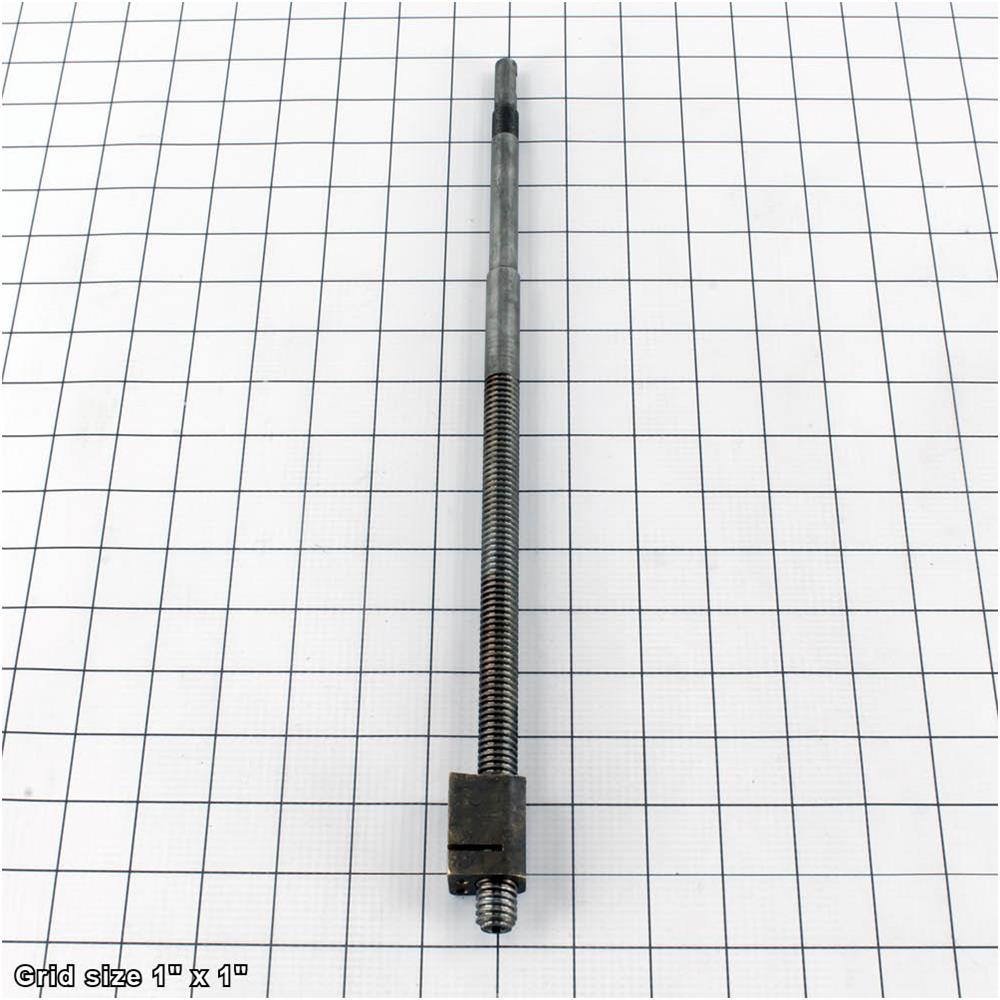

International instead of Jet, had it for years works great just looking for a little history and I need to build a new cross slide nut, looking for advice as well, I measured the thread and it is left hand acme 15mm 29 degree 8 pitch, some people say buy a tap, huge money some say machine that is around my neck of the woods in bc canada, thanks in advance for any help

International instead of Jet, had it for years works great just looking for a little history and I need to build a new cross slide nut, looking for advice as well, I measured the thread and it is left hand acme 15mm 29 degree 8 pitch, some people say buy a tap, huge money some say machine that is around my neck of the woods in bc canada, thanks in advance for any help