-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

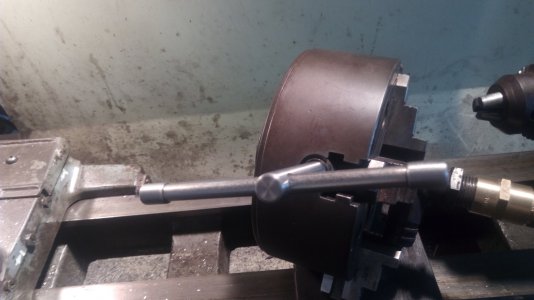

Atlas 10F V42

- Thread starter timmeh

- Start date

- Joined

- Aug 23, 2014

- Messages

- 214

- Joined

- Aug 23, 2014

- Messages

- 214

Attachments

- Joined

- Oct 10, 2018

- Messages

- 543

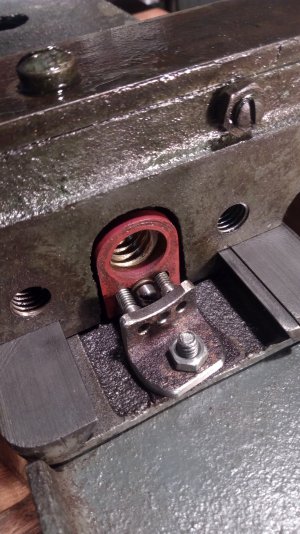

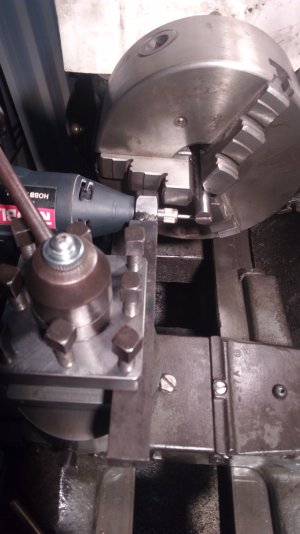

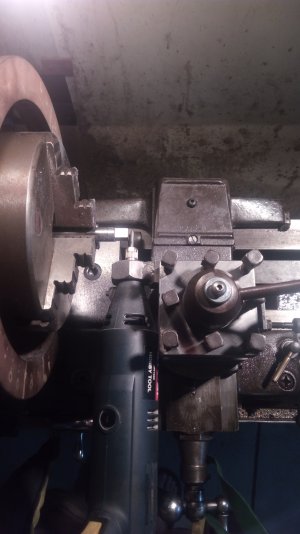

Thanks for sharing your mods. Lots of interesting stuff."Dremel" tool post mount sorted.

For the Dremel mount, it looks like you started with a nut that was the right size and thread? Is that a grub screw to lock in the Dremel?

I've thought about making something similar but I wasn't sure how securely the Dremel is held since it is only a few threads of engagement at the end of tool. How much does the unsecured end bounce around? Any concerns with the quality of the cuts it can make?

Thanks,

Craig

- Joined

- Aug 23, 2014

- Messages

- 214

Yes, nut is correct size(3/4, 10 or 11 TPI) no grub screw, just nipped up firm(it's only a plastic housing), didn't notice any vibration, too busy watching the pointy end.Thanks for sharing your mods. Lots of interesting stuff.

For the Dremel mount, it looks like you started with a nut that was the right size and thread? Is that a grub screw to lock in the Dremel?

I've thought about making something similar but I wasn't sure how securely the Dremel is held since it is only a few threads of engagement at the end of tool. How much does the unsecured end bounce around? Any concerns with the quality of the cuts it can make?

Thanks,

Craig

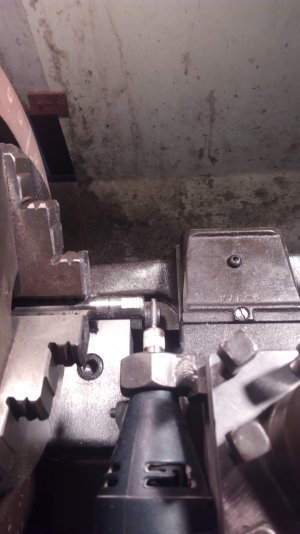

Small cuts, .5mm(.020") at the start, .15mm(.006") to finish and spring(deflection) cut after each cut.

Using 1/8 carbide burr as milling cutter.

Adjusting "carriage stop" as I go, to prevent cutter grabbing in the radius, particularly because I'm climb milling.