- Joined

- Nov 10, 2011

- Messages

- 1

Is there a reason to choose a piston type tool post rather than a wedge type?

Cost was the only reason for choosing the piston over the wedge. However, I have never regretted my choice of the piston as the cost difference was for me significant. As to performance I have never had any issues with the piston either, though I will admit there must be something better about the wedge to justify the cost difference. I think you are either pleased with a piston type or totally unhappy with them. I have seen a good bit of unflattering description attached to piston type posts written by many folks.

One more suggestion if you still have not made your purchase. If you buy your post according to the swing of the machine that matches what is shown for the post in the tool catalogs for an Atlas/Craftsman 12" machine you will select an AXA post. That was what I was going to purchase until a machinist friend suggested that I buy a BXA instead of an AXA. Initially I thought this a poor idea and believed the BXA would look like a hulking mass monted to the cross slide.

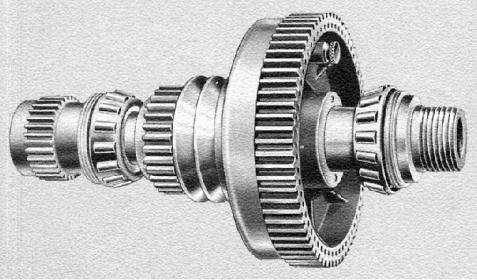

My friend pointed out that if I went with a BXA the difference would not be that great, but the primary reason for my selecting a BXA post was the fact that with the BXA you can later fit a sissors style knurling attachment that will fit one of your tool holders and allow you to knurl without having to put your little Craftsman/Atlas machine through the punishment of applying the great pressure to the little brass nut utilized on the cross slide. Anyone that has ever knurled with a regular type knurling tool holder that relys on pressure applied at the compound (and by extension that brass nut) knows that the amount of pressure one must apply to accomplish the knurl is punishing to an Atlas lathe. Other like sized lathes of heavier build such as a South Bend or a Logan or a number of others I am sure this is no big deal, but after doing a little knurling with my lantern style knurler I believe that is too much to ask of an Atlas, thus I found that the sissor style knurler is the best option for my Atlas machine.

If you never knurl or have no interest in that then I suppose there would no benefit to realize with a BXA tool post for a 12" Craftsman/Atlas machine. I hope this helps.