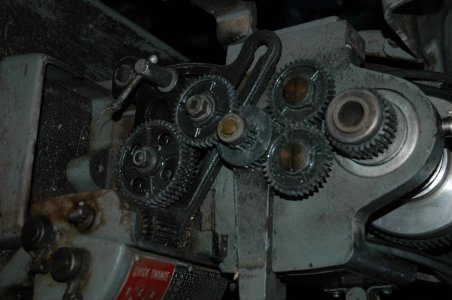

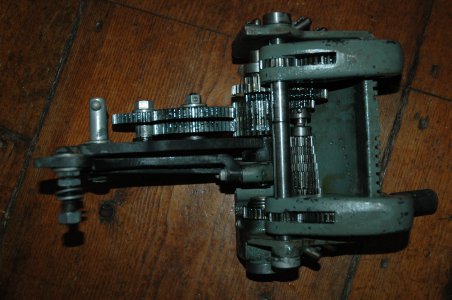

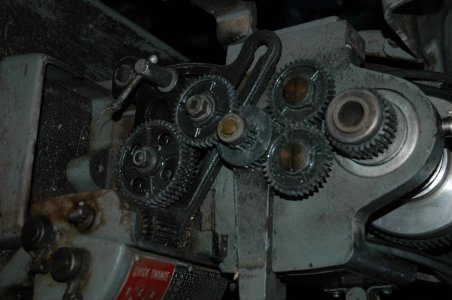

I just picked this thing up yesterday, dirty and sticky, but complete and lightly used. My goal with it is just a thorough disassemble and clean up, the paint seems to be in fine shape, and even under fairly intense scrutiny, nothing seems terribly worn.

I'm not quite sure where to look for a casting date on the bed, all I have been able to find appears to be a part number cast into the interior of the rear rail. I believe that it is a fairly early model, based on the serial number, but that is not really founded in any actual knowledge of production numbers.

I will try to document the process as best I can, and I'm sure questions will arise, but there seems to be a great deal of knowledge floating around on this site, so the answers will likely be found as well.

N

I'm not quite sure where to look for a casting date on the bed, all I have been able to find appears to be a part number cast into the interior of the rear rail. I believe that it is a fairly early model, based on the serial number, but that is not really founded in any actual knowledge of production numbers.

I will try to document the process as best I can, and I'm sure questions will arise, but there seems to be a great deal of knowledge floating around on this site, so the answers will likely be found as well.

N